- Reduced price

The Material Station transforms the UltiMaker S7 into a manufacturing powerhouse through automated material handling and storage.

The flexible steel build plate allows easy, toolless removal of 3D printed parts, making it possible to reset the UltiMaker S7 in a fraction of the time it normally takes. 25 magnets and 4 pins securely hold the plate in perfect alignment, allowing for one-handed operation. A sensor prevents a print from starting without the build plate present. And the flex plate's PEI coating reduces the need for glue or build plate adhesion structures for some materials.

The integrated Air Manager quietly filters the exhaust from every print on the UltiMaker S7. This process has been independently tested to remove up to 95% of ultrafine particles. It also fully encloses the build chamber. This and the single glass door leave fewer gaps to increase internal temperature stability and print quality, while giving you the freedom to place the printer anywhere – even next to open windows or HVAC systems.

3D prints succeed or fail because of their first layer. The new inductive sensor on the UltiMaker S7 more detects tiny variations in the build plate’s topography with less noise, increasing accuracy. Bed tilt is calibrated in the factory and automatically maintained, removing the need for thumbscrews and the chance of user error. Together these allow you to start a print and walk away – more confident than ever in a perfect first layer.

Checking on your print remotely via UltiMaker Digital Factory never looked better. The new 1080p camera in the UltiMaker S7 is mounted higher to give a better view of the first layers. A continuous video feed update is coming later in 2023.

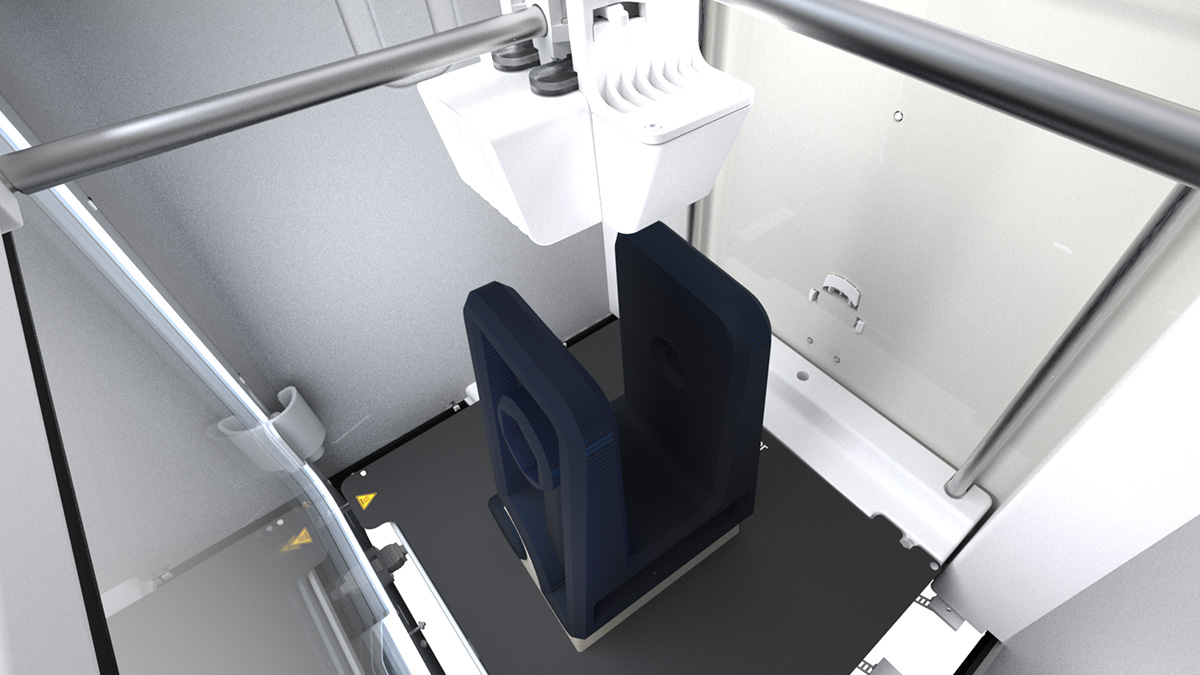

Seamlessly integrating with the Ultimaker S7, the Material Station redefines filament storage and delivery, unlocking truly 24/7 dual extrusion.

Inside the humidity-controlled chamber, six material spools can be loaded in any order with up to 4.5 kg of material. Each bay features automatic material switching, composite-ready feeder wheels, and filament flow sensors.

Ideal for keeping your UltiMaker print cores in optimal condition

Quick-swap nozzles for build and water-soluble support materials. Available in 0.25, 0.4, and 0.8 mm

Hardened steel nozzle for printing abrasive glass and carbon fi ber composites. Available in 0.4 and 0.6 mm

Remove water-soluble PVA support material up to 4X faster.

Ultimaker software empowers your teams to scale 3D printing innovation across your organization, with a subscription plan for every need.

No customer reviews for the moment.