Raise3D E2CF

Carbon Fiber 3D Printing Made Simple

Choose RaiseShield, the extended warranty for Raise3D products.

E2CF is a desktop 3D printer developed by Raise3D for carbon fiber-reinforced filaments and other composite materials.

Carbon fiber filament has low density, high strength, and it is resistant to corrosion, static electricity and high temperature. It has potential for a wide range of applications within industries that need considerable strength-to-weight ratio in their solutions, such as the aviation industry and the automotive world. The E2CF is durable, user-friendly and stable while in operation, delivering accurate prints.

The new silicon carbide nozzles have excellent wear resistance and thermal conductivity, which will effectively lessen the abrasion the carbon fiber composite filament subjects the nozzle to when printing, making the nozzle more durable.

*Nozzles made of other materials suitable for printing carbon fiber filaments will be launched in the future.

The gears are made of high-hardness steel and have been heat-treated for better wear resistance.

With a custom gear tooth profile, filament is firmly held in place to ensure that it does not slip when extruding. The force of the system is enhanced to ensure the stability of printing.

The E2CF is compatible with Raise3D’s Industrial PA12 CF Filament and the high-performance carbon fiber filaments certified by the Raise3D Open Filament Program, such as PA CF/PET CF/PPS CF (printing Temp. between 280-300 °C) from Forward AM and LEHVOSS.

The Raise3D Industrial PA12 CF Filament is reinforced with short carbon fibers, and exhibits excellent rigidity and strength, heat resistance, low warpage, and low water absorption. Meanwhile, this material has an outstanding strength-to-weight ratio, and will obtain enhanced mechanical property and dimensional stability after annealing, which makes it suitable to replace metal in the manufacturing of certain lightweight components.

Raise3D Industrial PA12 CF Support Filament is a break-away support material specially developed for carbon fiber-reinforced composite filaments. During the 3D printing process, it creates a stable support structure, providing proper adhesion to printed surfaces and counteracting any tendency to warp.

As such, it significantly improves the surface quality of the overhangs and hollows of the printed items. After a print is finished, the support structure can be easily removed or broken away from the printed parts. This support material exhibits a broad compatibility with many Raise3D OFP (Open Filament Program) certified high-performance carbon fiber-reinforced composite filaments, and is more cost-effective when compared with water-soluble support material.

The built-in suspension trays are used to place the filament and allow material to be pulled more smoothly. When closed, they can effectively prevent dust and moisture from affecting the material, for a period of up to 30 days*.

*From Raise3D test data.

The E2CF has slicing profiles that have been repeatedly tested and verified by our engineers in ideaMaker. There is no need to adjust the parameters before printing. Enjoy easy and high-quality printing.

Like other Raise3D products, the E2CF can carry out mass production and intelligent management using ideaMaker as the core software solution.

Carbon fiber composite materials have many applications, including functional prototypes, aerospace, automotive, medical, sports equipment, civil engineering, electronics, and other fields. It also has the further potential for a variety of uses, such as fixtures in a mechanical workshop, prosthetics, and customized bicycle frames.

Medical

High strenght, lightweight, heat-resistant

Automotive

Abrasion-resistant, lightweight, rust-proof

Industrial

Strong, drop-resistant, with special matte surface finish

Aerospace

Abrasion-resistant, corrosion-resistant, electrostatic-resistant

High-quality & User-friendly

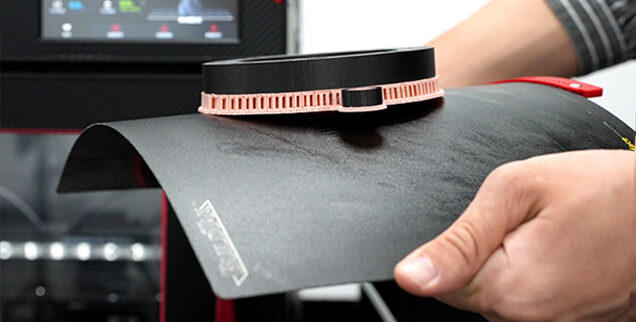

Professional 3D printers, like the E2CF, are quality, user-friendly printers, designed with features to ensure the best possible printing results. For example, the E2CF has a flexible build plate, which allows 3D printed parts to be easily removed, while minimizing potential damage to the part during removal. It is features like the flexible build plate that help make the E2CF a user-friendly and industrial beginner 3D printer for those who wish to gain experience in the area of professional 3D printing.

Auto Bed Leveling

Bed leveling is the process of confirming that the printing platform is as level as possible. The E2CF has this leveling procedure as an automated function. Auto bed leveling will maintain the distance between the print nozzles and the bed, to create a uniform build area. This improves bed adhesion and allows the extruder to adjust to even the most minor of surface contour changes for better final print quality.

Camera

The E2CF uses a camera to monitor the entire 3D printing process of every print job. This camera operates by connecting to RaiseCloud, allowing users to keep track of every print job remotely and while on the move. This ability to check the 3D printing process gives peace of mind.

| GENERAL | ||

| Build Volume (W×D×H) | Single Extruder Print: 330×240×240 mm Dual Extruder Print: 295×240×240 mm |

|

| Machine Size (W×D×H) | 607×596×465 mm | |

| Print Technology | FFF | |

| Print Head System | IDEX Independent Dual Extruders | |

| Filament Diameter | 1.75 mm | |

| XYZ Step Size | 0.78125, 0.78125, 0.078125 micron | |

| Print Head Travel Speed | 30–150 mm/s | |

| Build Plate | Flexible Steel Plate with Buildtak | |

| Max Build Plate Temperature | 110 ºC | |

| Heated Bed Material | Silicone | |

| Build Plate Leveling | Mesh-leveling with Flatness Detection | |

| Filament Run-out Sensor | Available | |

| Supported Materials | PA12 CF, PA12 CF Support, OFP Certified Third-Party Filaments | |

| Layer Height | 0.01 – 0.25 mm | |

| Nozzle Diameter | 0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available) | |

| Hot End | V4P | |

| Max Nozzle Temperature | 300 ºC | |

| Connectivity | Wi-Fi, LAN, USB port, Live camera | |

| Noise Emission (Acoustic) | <50 dB(A) when building | |

| Operating Ambient Temperature | 15-30 ºC, 10-90 % RH non-condensing | |

| Storage Temperature | -25 ℃ to +55 ℃, 10-90 % RH non-condensing | |

| Filter | HEPA filter with activated charcoal | |

| EVE Smart Assistant | Available | |

| Net Weight | 32.4 kg | |

| Gross Weight (Carton Only) | 36.7 kg | |

| Gross Weight (Carton with Pallet) | 45.4 | |

| ELECTRICAL | ||

| Power Supply Input | 100-240 V AC, 50/60Hz 230 V @ 2A | |

| Power Supply Output | 24 V DC, 350 W | |

| SOFTWARE | ||

| Slicing Software | ideaMaker | |

| Supported File Types | STL/ OBJ/ 3MF/ OLTP | |

| Supported OS | WINDOWS/ macOS/ Linux | |

| Machine Code Type | GCODE | |

| PRINTER CONTROLLER | ||

| User Interface | 7-inch Touch Screen | |

| Network | Wi-Fi, Ethernet | |

| Power Loss Recovery | Available | |

| Screen Resolution | 1024×600 | |

| Motion Controller | Atmel ARM Cortex-M4 120MHz FPU | |

| Logic Controller | NXP ARM Cortex-A9 Quad 1 GHz | |

| Memory | 1 GB | |

| Onboard Flash | 8 GB | |

| OS | Embedded Linux | |

| Ports | USB 2.0×2, Ethernet×1 | |

No customer reviews for the moment.