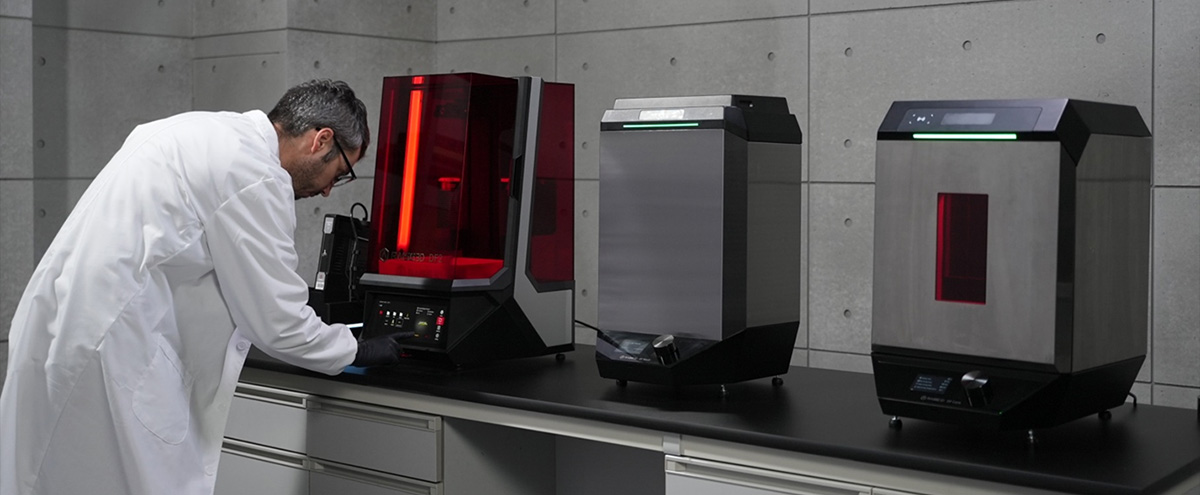

The Raise3D DF2 solution is a Digital Light Printing (DLP) printing system that provides fast printing speeds, smooth surfaces, high precision, and exceptional reliability. It is designed for engineering prototyping, manufacturing aids, and low-volume production using a wide variety of high-performance resins. Discover the efficient workflow via RFID as we redefine the possibilities of resin 3D printing.

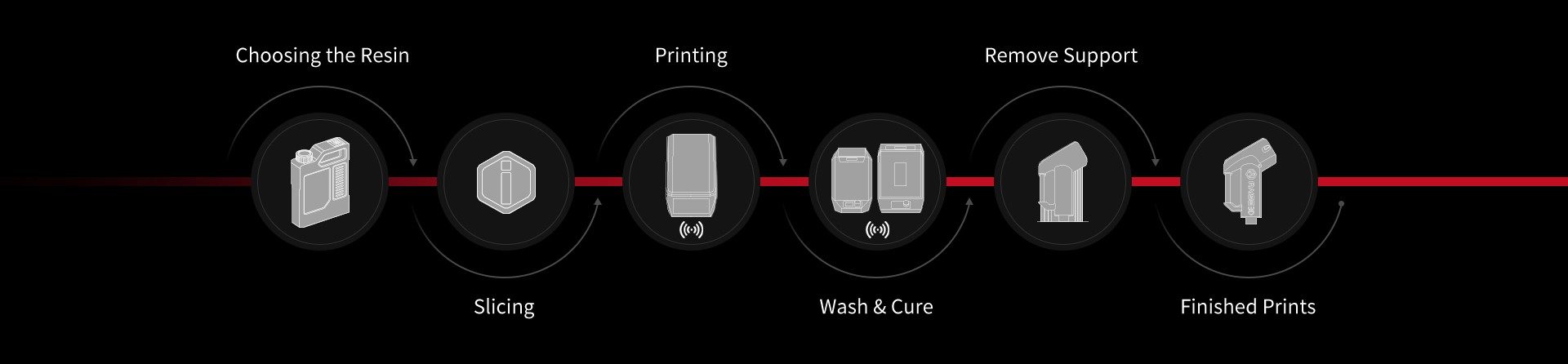

The Raise3D DF2 solution utilizes RFID technology to seamlessly integrate hardware, software, and materials, offering users a streamlined workflow without the need for manual entry of process settings. This not only saves operational time but also ensures a consistent workflow, which is critical for production.

Compared to the time-consuming and messy workflow of DLP, the Raise3D DF2, DF Wash and DF Cure come with an RFID-tag-integrated smart build plate and a logical interface that ensures a cleaner and simpler workflow throughout the printing, washing and curing process. This not only streamlines manual operations but also ensures your printing tasks are always accomplished with the same print results.

A DLP 3D printer designed for small batch production with high precision, repeatability and reliability.

Process controllable, efficient, easy maintenance and automatic cleaning solution.

A powerful curing station with multiple, traceable and customizable UV curing and heating profiles.

Raise3D High Performance Engineering Resins: Meet demands for customized small batch production of precise prototyping and industrial engineering parts.

ORP (Open Resin Program):The aim of the ORP is to open to third-party resin manufacturers to develop high-performance resins, including co-branding with Forward AM and Henkel, to provide customers with a wider range of resin options.

Easy-to-print resin for prototyping and design

High-resolution material for detailed models

Tough and durable resin for functional applications

Material with high strength, rigidity and heat-resistance

Raise3D has partnered with third-party resin manufacturers such as Forward AM and Henkel to develop co-branded resins. This collaborative effort makes these resins an ideal choice for applications ranging from prototyping to intricate engineering projects.

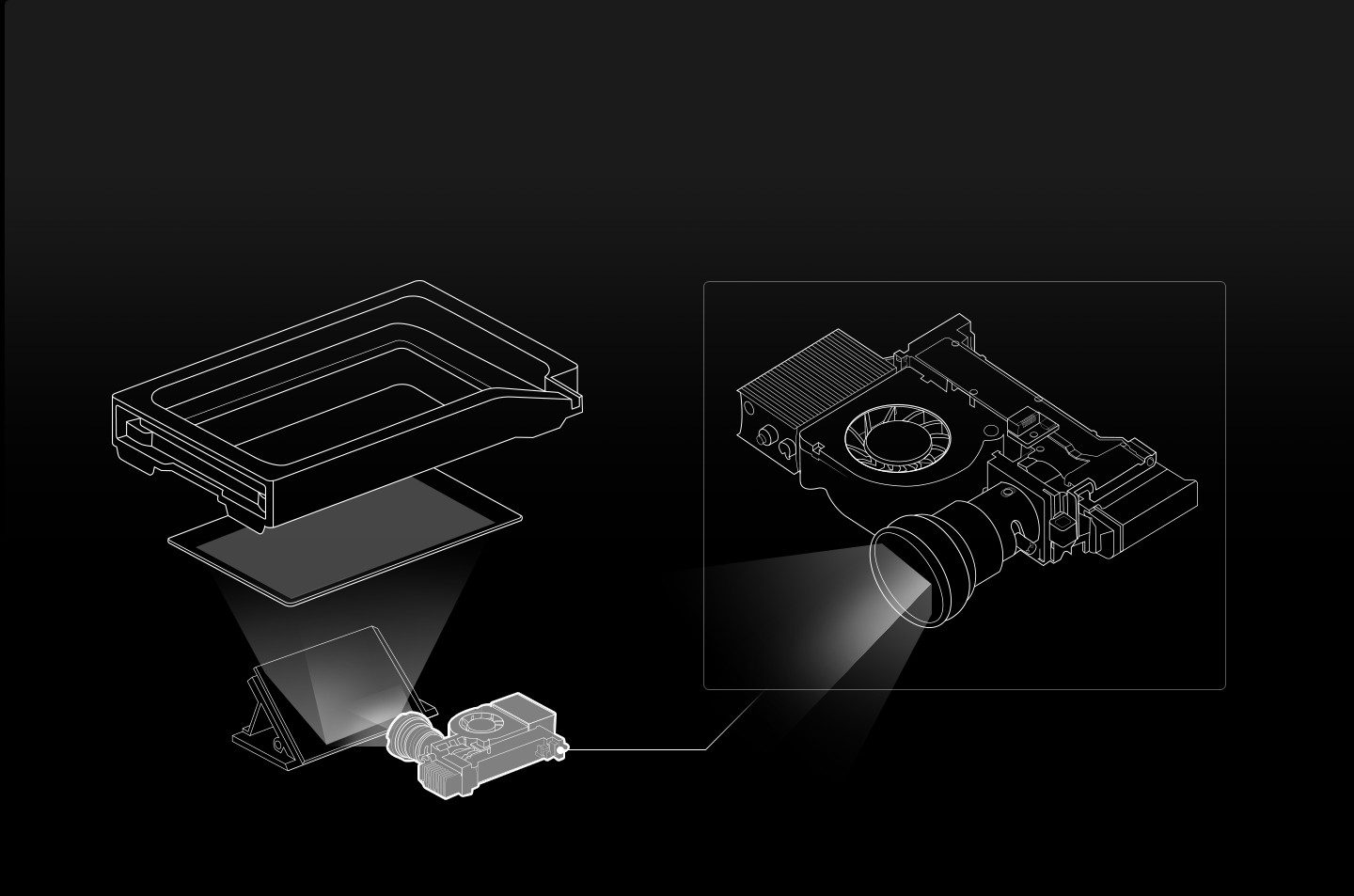

XY Pixel: 78.5 μm

XY Resolution: 2560 x 1440 (2K)

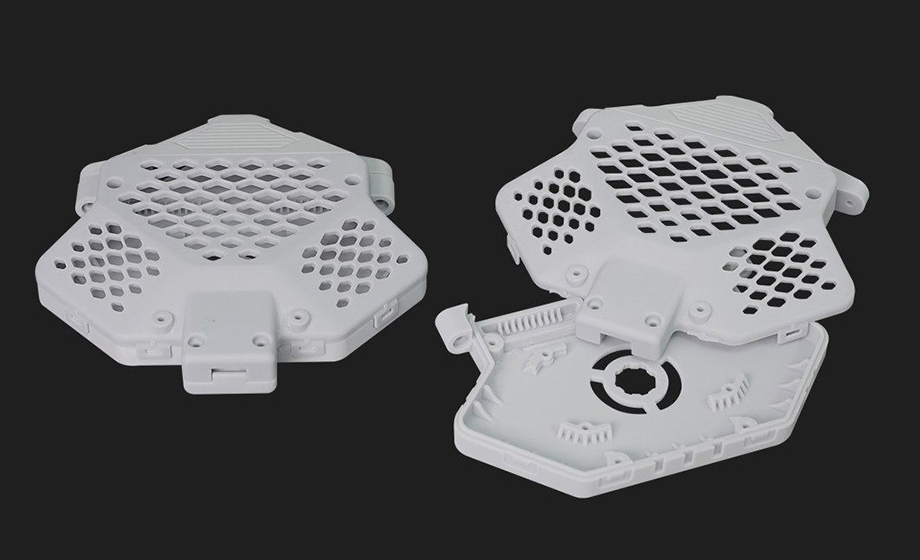

From intricate model designs to complex engineering prototypes, Raise3D DF2 adopts top performing optical components, so that every detail is captured with the utmost accuracy.

Bigger, Faster, Better

200 x 112 x 300 mm

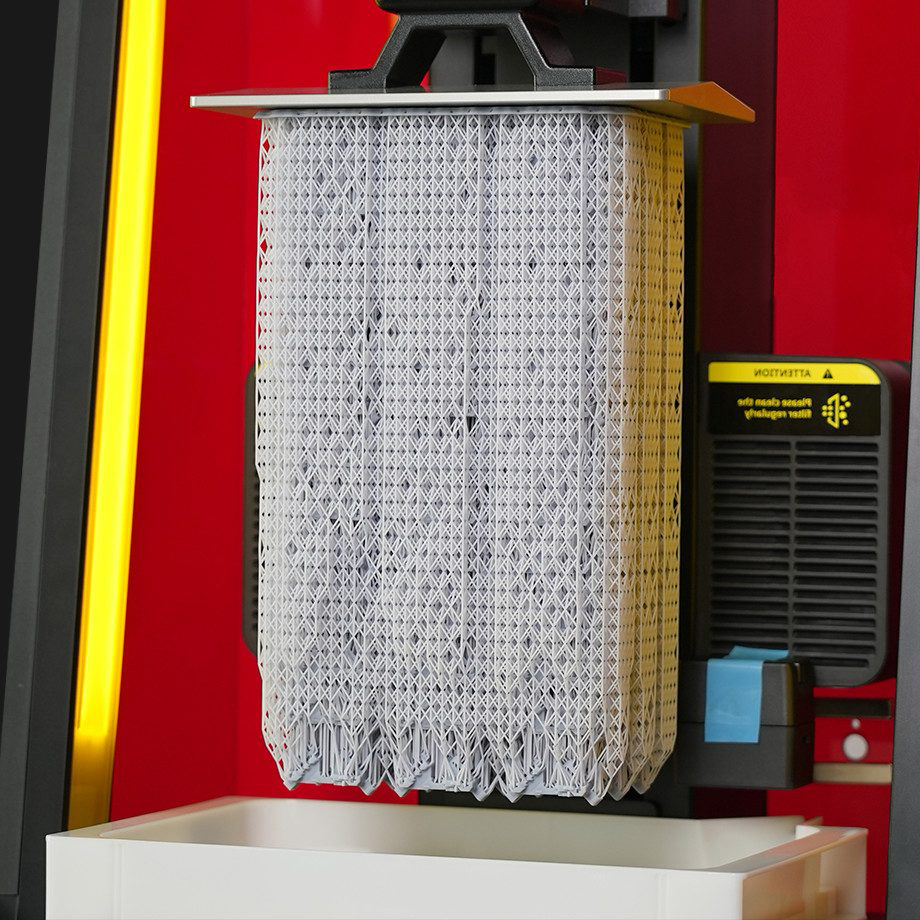

Max. up to 12 kg

From large-scale prototypes to intricate models, Raise3D DF2 printer makes it easy.

The Raise3D DF2 adapts effortlessly to the scale of production and maintains consistent quality.

RFID automatically stores and reads the relevant parameters of an entire workflow for printing, washing and curing, and is easy to mount and unmount, reducing the need for tedious manual operations.

Maximum load capacity of 200 kg for Z-axis. Features no staggered layers and high movement accuracy, ensuring the stability of printing large parts and extended use.

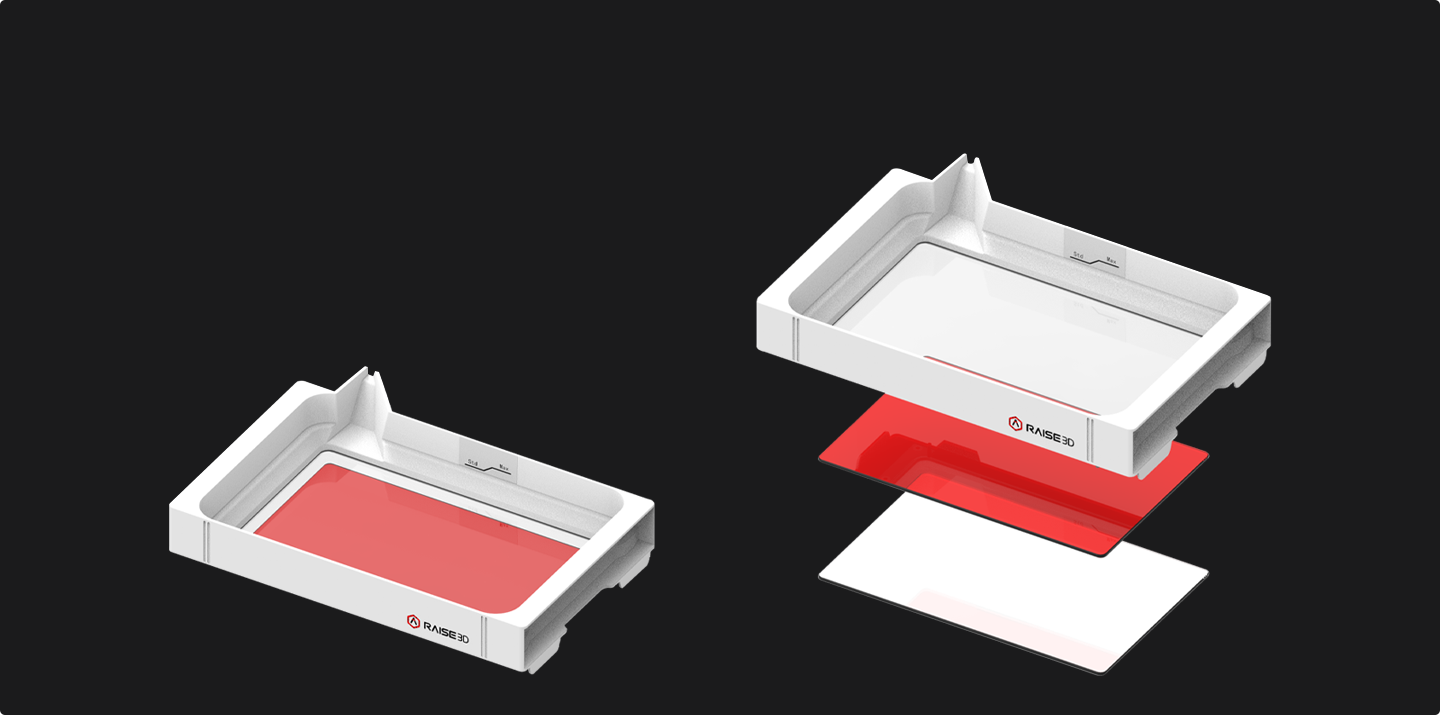

Air peel design between the resin vat bottom and the highly clear glass reduces the force from 50 kilograms to 10 kilograms, effectively peeling each layer and ensuring successful printing.

High-quality optical components are used throughout the entire optical path projection system to reduce loss, eliminate dispersion, ensuring the reproduction of sharp layers.

ideaMaker has added multiple new features that are compatible with Raise3D DF2 printer, reducing learning curves and improving the success rate of DLP printing.

Print Technology: DLP

Build Size (W×D×H): 200 x 112 x 300 mm

Machine Size (W×D×H): 450 x 400 x 730 mm

XY Pixel Size: 78.5 micron

XY Resolution: 2560 x 1440

Max Z Workload: 12 kg

Max Printing Speed: 25 mm/h (0.1 mm per layer)

Layer Height: 50-100 micron

Resin Level Detection: Yes

Auto Resin Refill: Yes

Control Panel: Touch Screen (1920 x 720, Magic Layout)

RFID Print Platform: Yes

Level Calibration: Calibrated in Factory

Chamber Heating: Yes (Max. 40℃)

Machine Size (W×D×H): 400 x 410 x 646 mm

Washing Tank Volume: 14L

Max. Washing Volume: 200 x 112 x 300 mm

Compatible Solvent: IPA, Water, TPM

RFID Print Platform: Supported

Automatic Liquid Drainage: Yes

Machine Size (W×D×H): 490 x 400 x 610 mm

Max. Curing Size: φ230 x 300 mm

Net Weight: 31.95 kg

Gross Weight: 45.5 kg

Curing Source: LED (365nm, 385nm, 405nm mixed); Air Heating (Max. Temperature: 120℃)

Raise3D DF2 Complete Package

This Complete Package includes the hardware and the software needed for printing.

Components:

Total Value: € 7.497

Complete Set Price: € 6.999

No customer reviews for the moment.