3D Printing in the footwear industry

The footwear industry is constantly changing. There is a constant desire for original ideas and designers and artisans are moving the boundaries of the art of footwear, thanks to 3D printing.

Thanks to the help of 3D printers it's possible to produce realistic functional prototypes in a few hours, ready to be tested before the actual production starts.

The possibility to modify and evaluate the design several times, even during the same day, represents a huge advantage. 3D printed shapes, uppers and maquettes, combining different materials with different densities, allow a considerable increase in production efficiency.

And we're not just talking about prototypes. The trend is also to produce accessories and final parts, up to the realization of the shoe completely 3D printed.

There are more and more 3D modeling software specialized in footwear design. From the first design phases to the design of shapes and molds, from cost forecasting to production process control, to 3D printing.

Ultimaker, an added value

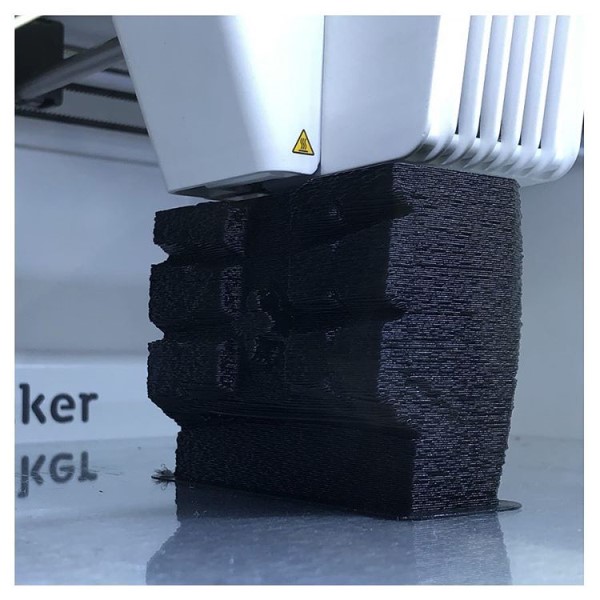

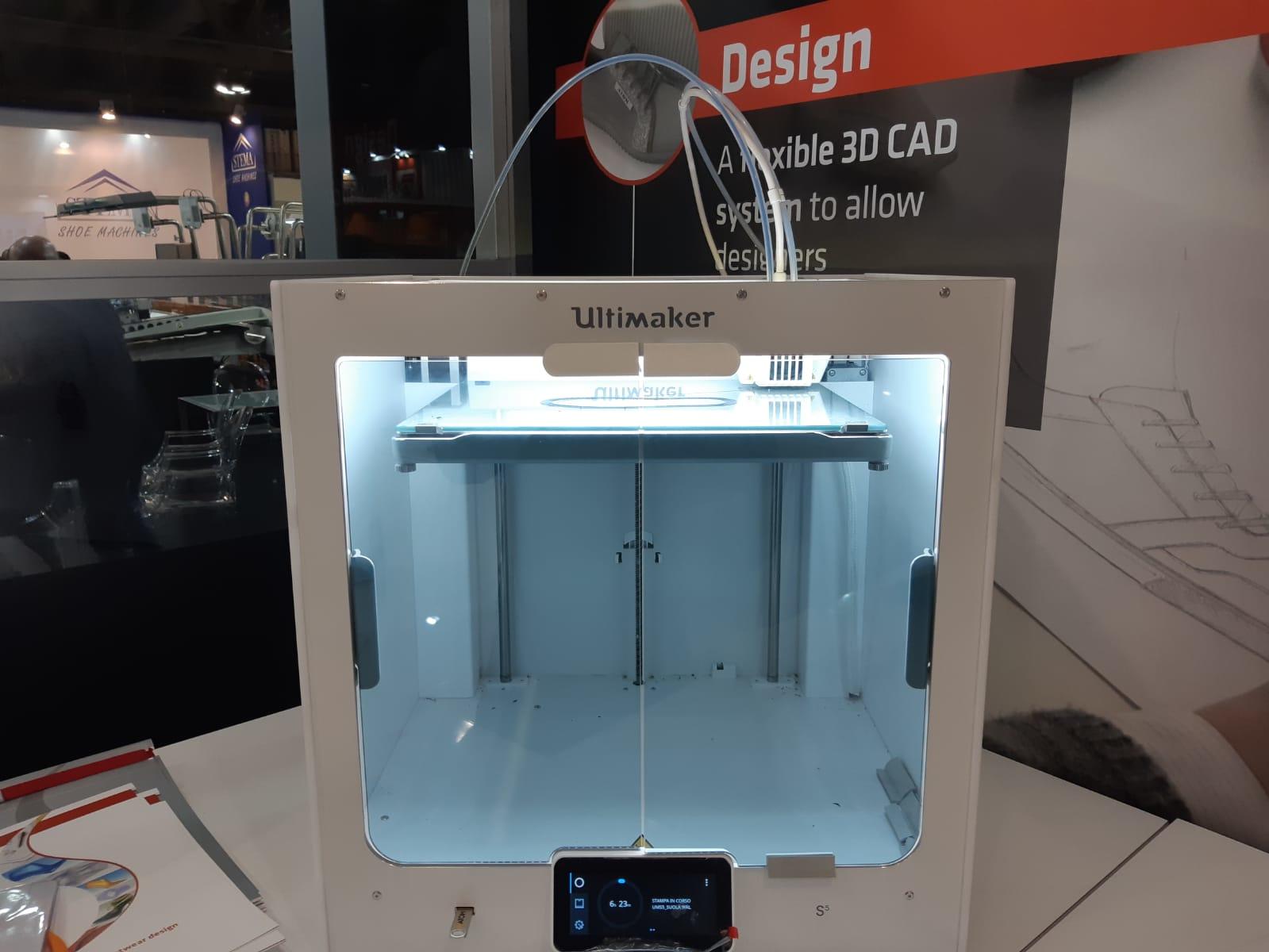

Ultimaker 3D printers, and in particular the Ultimaker S5, are chosen by designers around the world for their ease of use, print volume, and the possibility of experimenting with various combinations of materials thanks to the double extruder.

EXAMPLES AND APPLICATIONS

Construct:10061 | Rethink footwear design

Construct:10061 is a Timberland project. Every six months a team of creators and innovators tries to rethink the footwear production process. In the last edition of April 2019, Ultimaker S5 3D printers played a key role in project development.

Atelier 27: custom 3D printed heels

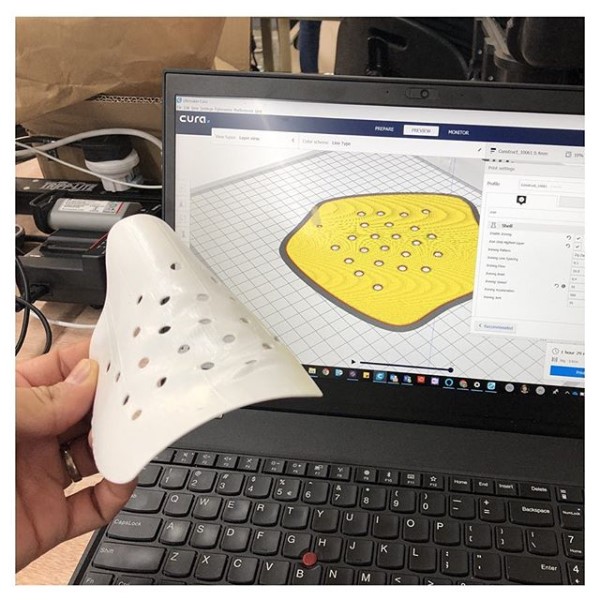

The Atelier 27 event is the product of Eram and Unistudio’s collaboration. Customers can get hands on and use a special app in the store to personalize the design of the shoes’ heels.

Big or small heel? Stripes? Stars or cactus? No problem!

Once the design is finished, the app turns it into an STL file ready to 3D print with Ultimaker 3D printers.

The outer shell of the heel is printed in under one hour then attached to the sole of the shoe.

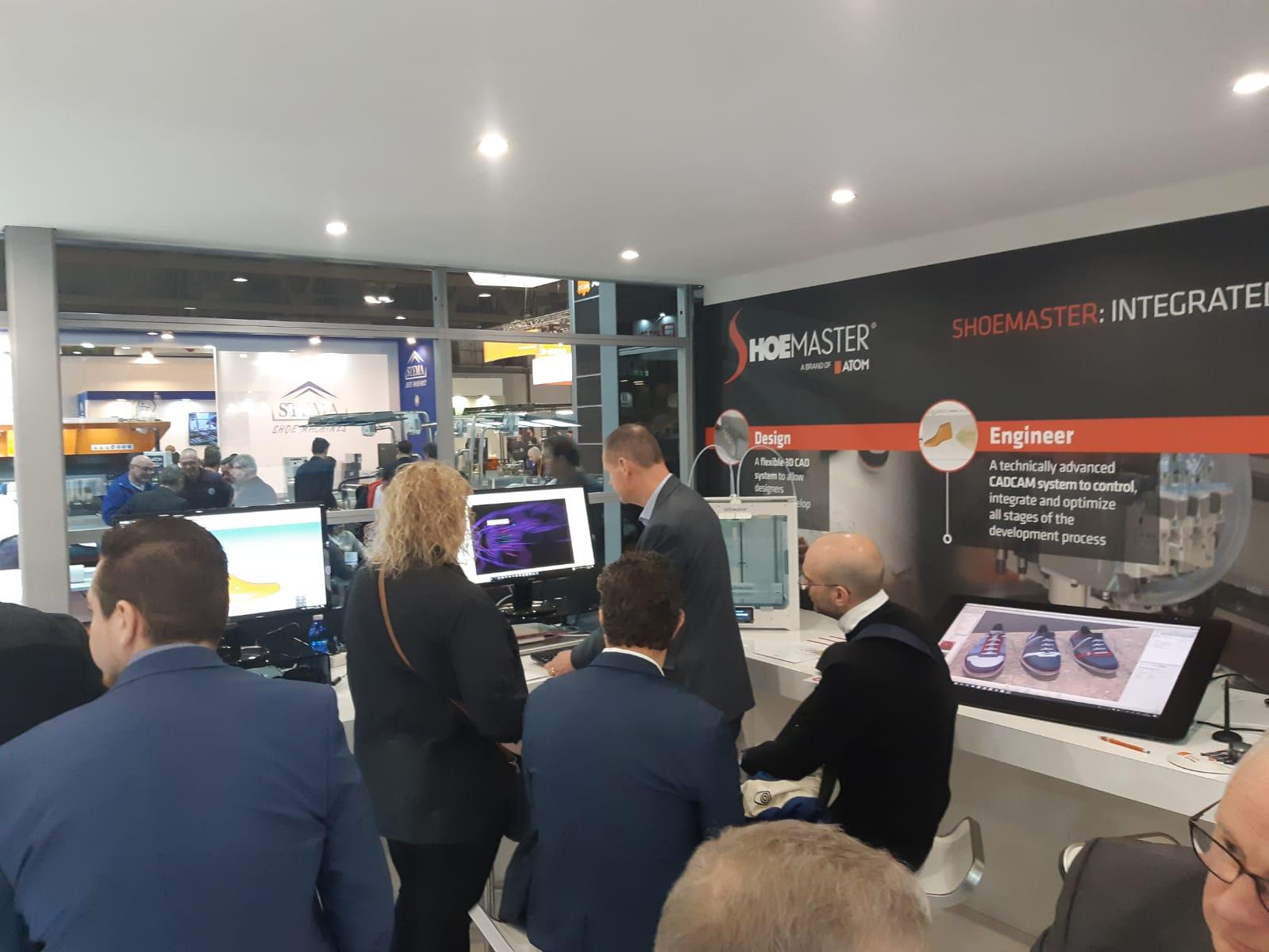

SIMAC Tanning Tech 2019

Shoemaster® is a CAD / CAM system specialized in providing 2D and 3D solutions for the footwear industry. It's a brand of Atom SpA and is used by more than 800 footwear companies. During the Simac Tanning Tech, the international event with the most qualified offer of machinery and technology for the footwear, leather goods and tanning industries, visitors were able to appreciate the results of this new production process.

Credits:

In Same Category

Related by Tags

- Krones: Optimized 3D-printed parts & spares for customers anywhere

- 3D printing for the production of sheet metal bending dies

- Bambu Lab X1E: multifilament 3D printing in industrial applications

- 3D printing for the Education and STEM disciplines: the FabLab Poliba experience

- 3D printing and footwear: the FuSa shoe

Leave your comment