3D Printing: the new feature of NTEK

NTEK is an Italian company specialized in products and services for the measurement and control of noise and vibration derived from it, in all fields of application of acoustics.

Within the range of proposed solutions, the dodecahedral sources of the OMNI series stand out, used to radiate uniformly a sound in all directions, allowing a correct insulation measurement and reverberation time both in building and architectural acoustics.

Recently NTEK revolutionized the production process of the Omni 4" Series focusing on 3D printing, and entrusting the creation of new products to Crea 3D, their technological partner also for the development of the design of the new dodecahedra.

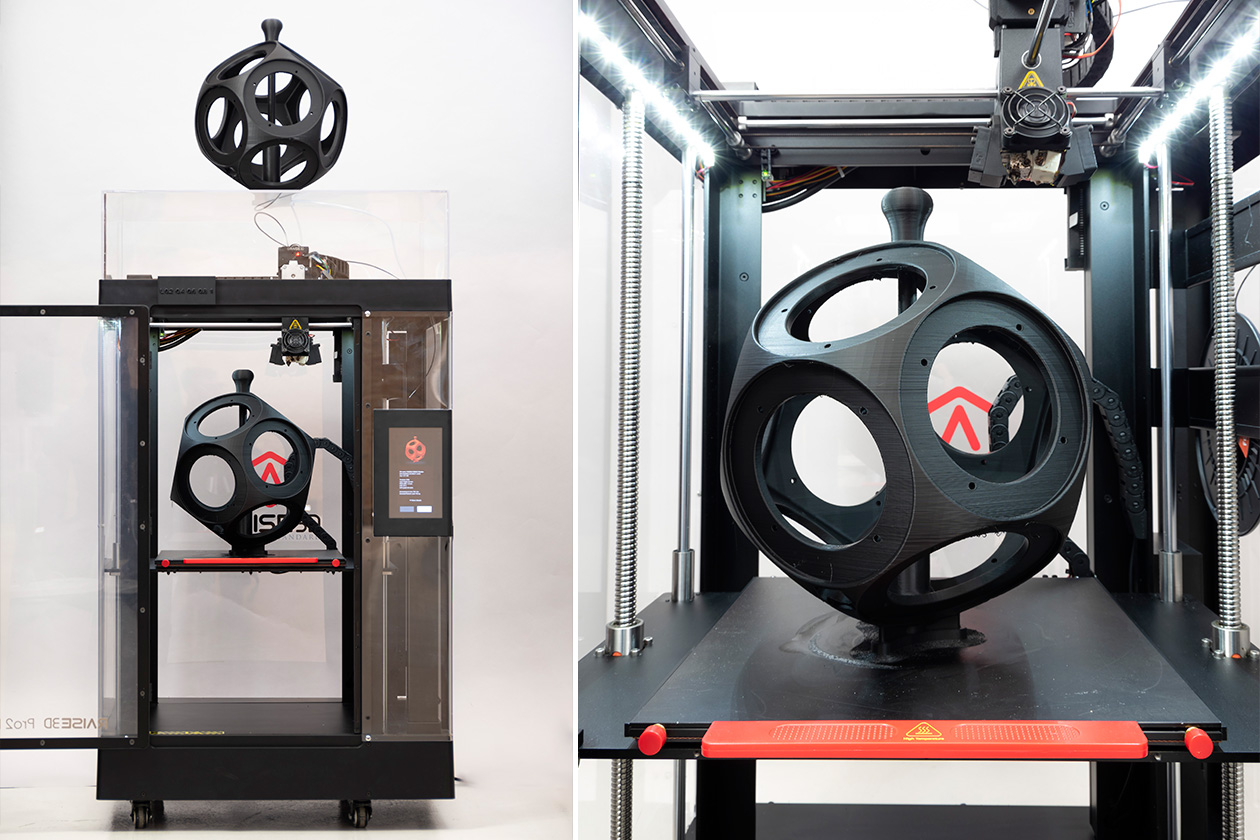

The 3D printing process

For the printing of the new Omni 4 ’’ Crea 3D used Raise3D large format 3D printers, and the Fabbrix PLA HT filament.

The advantages of 3D printing

The traditional Omni 4 "were made of wood (Finnish birch), which guaranteed excellent product performance. The production, entrusted to an external supplier, required high quantities to amortize also the costs of the mold, with very long delivery times (a few months).

It was unthinkable to make changes during construction, even small ones, since they required the creation of a new mold, with additional costs and a considerable lengthening of delivery times.

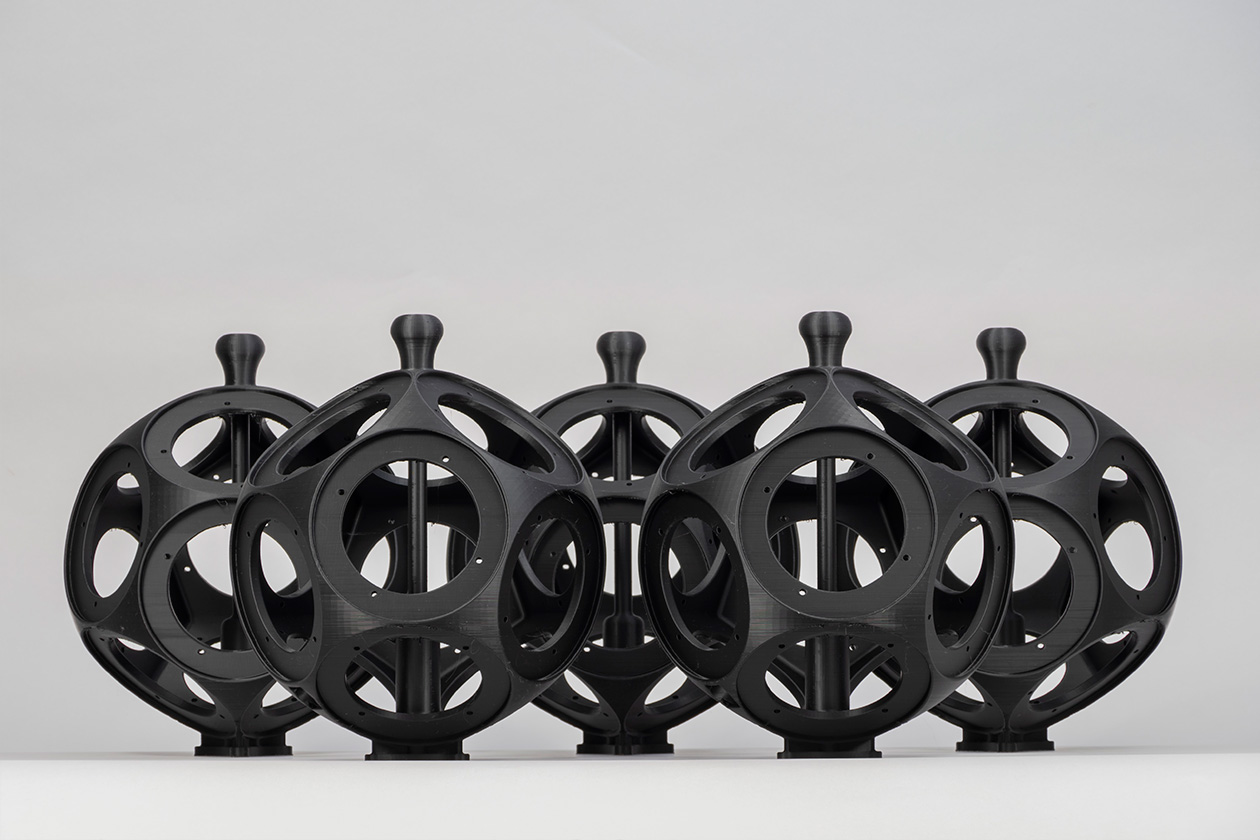

The new Omni 4 "printed in 3D represent the real breakthrough. Production with additive technology, in addition to allowing greater freedom in design, guarantees with its sphericity the achievement of greater isotropy and omnidirectionality.

3D Printed with heat-resistant material, they ensure excellent performance of the structure even after long periods of activity, without incurring deformations due to the temperatures reached during operation.

Moreover:

- Designed according to the needs and requirements, the new Omni 4″ guarantee greater ergonomics: hand transport will be more comfortable thanks to the new structure of the knob, which now ensures a more comfortable and firmer grip.

- The product is much lighter and more manageable than the traditional wooden version:

- 3D printed OMNI 4 HP: 7 Kg instead of 8,5 Kg.

- 3D printed OMNI 4 Lt: 4,2 Kg instead of 5,5 Kg. - Time savings, the possibility of printing even small quantities based on customer requests or market needs, and above all the possibility of making changes during the work, prevail over the economic aspect

“What started out as a simple internal prototyping, in the name of new technologies, is now proving to be a major workhorse. The first to adopt this new method: we feel proud to have invested and continue to invest in the field of new technologies and, where possible, make the best of them by directly modifying the production lines of Ntek"

Giancarlo Sassi, Ntek General Manager

In Same Category

Related by Tags

- 3D printing for the production of sheet metal bending dies

- Bambu Lab X1E: multifilament 3D printing in industrial applications

- Fireproof additive manufacturing: the benefits of flame retardant materials in modern industry

- Raise3D Announces the Launch of the DF2 Solution at Formnext

- 3D printing and footwear: the FuSa shoe

Leave your comment