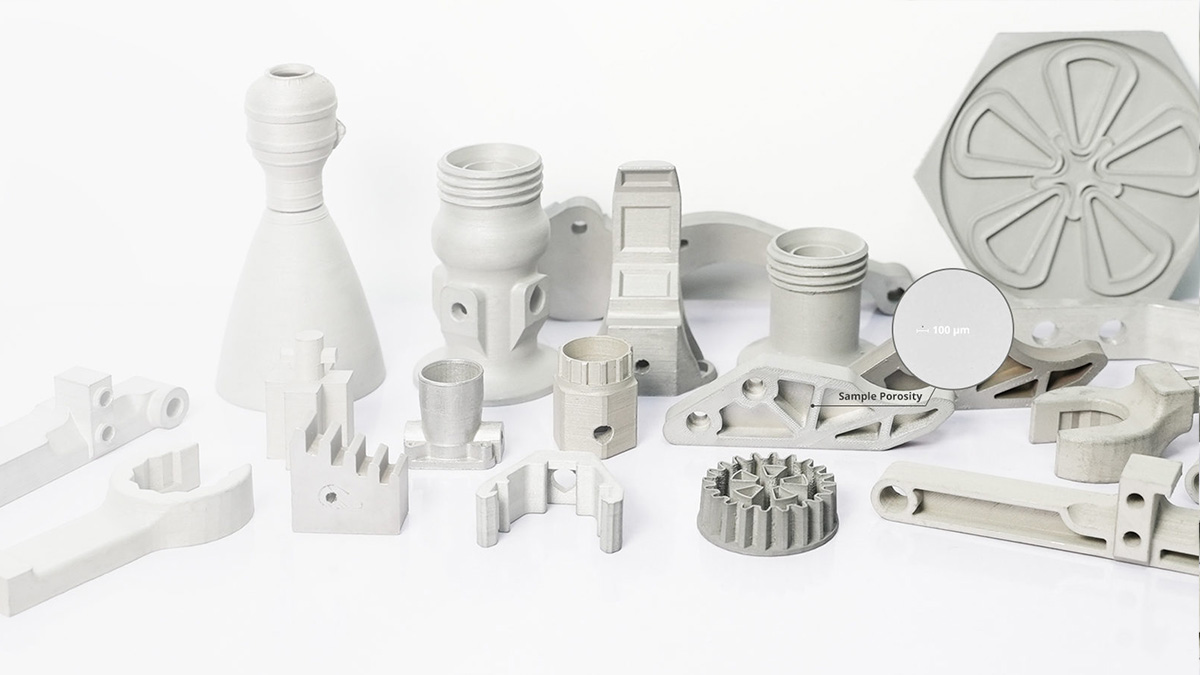

Metalfuse offers a complete solution, consisting of an indirect metal 3D printing process, paired with a special edition of ideaMaker compatible with MIM equipment. With this solution, Metalfuse’s advantages include low overhead costs and the ability to perform batch production. Metalfuse saves more energy and is more environmentally friendly when compared to processes such as CNC and SLM (Selective Laser Melting).

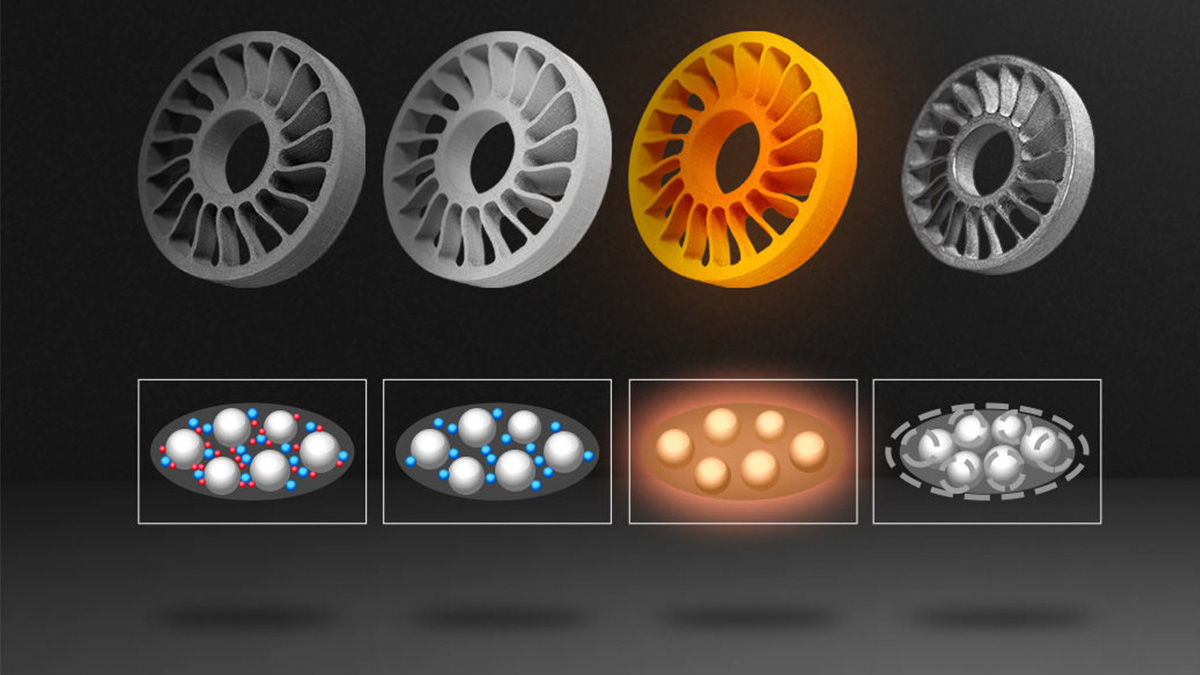

MetalFuse utilizes the Catalytic Debinding process, which leads to 60% off in processing time, and an increase of the part’s density to up to 97% of wrought iron’s density.

By using Forward AM’s metal filaments Ultrafuse 316L and Ultrafuse 17-4 PH, Metalfuse is capable of better printing repeatability and a greater yield rate.

The catalytic debinding furnace (D200-E) and the sintering furnace (S200-C) are used to post-process the “Green Parts”, in a way similar to the process developed based on Forward AM’s know how coming from Metal Injection Molding (MIM).

A special edition of ideaMaker offers templates optimized for this kind of printing, while taking into account the sintering and debinding process that can be paired with Metalfuse. This special edition ideaMaker also features a simpler slicing process.

A visual interface that needs only one click to select a template, and keeps stored work history available for review.

Filters that clean exhaust gas, bringing them to safe levels and reducing pollution.

Information sent through this form will be used for the provision of the requested services. I have read and ACCEPT unreservedly the Privacy policy, and I AUTHORIZE the treatment of my personal data.

| Forge1 | ||

| Machine Size (W×D×H) | 620 × 626 × 1390 mm | |

| Build Volume (W×D×H) | 300 × 300 × 300 mm | |

| Print Technology | FFF | |

| Print Head | Dual-Head with Electronic Lifting System | |

| XYZ Positioning Resolution | 0.78125, 0.78125, 0.078125 micron | |

| Print Speed | 30-150 mm/s | |

| Max Build Plate Temperature | 120 ºC | |

| Supported Materials | Ultrafuse® 316L, Ultrafuse®17-4 PH | |

| Filament Diameter | 2.85mm | |

| Max Nozzle Temperature | 300 ºC | |

| Connectivity | Wi-Fi, LAN, USB port, Live camera | |

| Operating Ambient Temperature | 15-30°C, 10-90% RH Non-Condensing | |

| Slicing Software | ideaMaker Metal | |

| Supported File Types | STL/ OBJ/ 3MF/ OLTP | |

| Supported OS | WINDOWS | |

| Ethanedioic Debinding D200-E | ||

| Machine Size (W×D×H) | 806 × 905 × 1583 mm | |

| Build Volume (W×D×H) | 200 × 200 × 200 mm | |

| Trays | Adjustable Multi-Level Tray (7 Positions) | |

| Protection Gas | Argon or Nitrogen | |

| Max Catalyst Storage | 2 L/ 122 inch³ | |

| Max Gas Flow | 5 L/min | |

| Max Debinding Speed | 1.55 mm/h | |

| Power Supply Input | 220-230 V AC, 50/ 60 Hz, Single phase, 20A, 4.4 kW Peak Draw | |

| Exhaust Treatment | Activated Carbon Adsorption Facilities | |

| Sintering (Carbon) S200-C | ||

| Machine Size (W×D×H) | 1434 × 1137 × 1974 mm | |

| Build Volume (W×D×H) | 200 × 200 × 200 mm | |

| Sintering Processing Time | About 20 hours | |

| Trays | Adjustable Multi-Level Tray ( 6 Positions ) | |

| Protection Gas | Argon, Nitrogen | |

| Max Heat Load | 14 kW | |

| Peak Internal Temperature | 1450 °C | |

| Power Supply Input | 380-400 V AC, 50/ 60Hz, 3-Phase (5-wire), 45A/ 30 kW Peak Draw | |

| Front-Mounted E-Stop | Yes | |

| Over-Heating Protection | 1500 °C | |

Write your review

No customer reviews for the moment.