A High Temperature Extruder

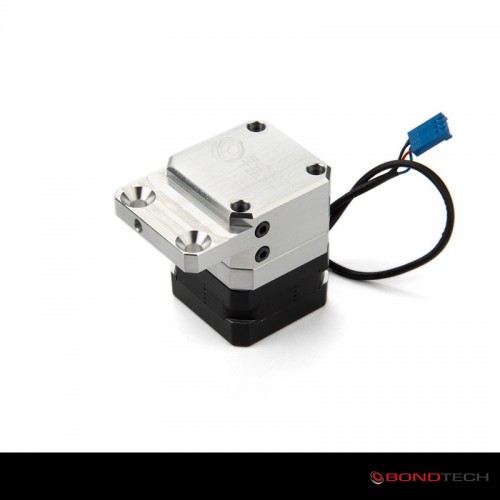

The BMG-HT for the Intamsys Funmat HT is a high temperature upgrade kit based on our popular Bondtech Mini Geared (BMG) Extruder.

It has a milled Aluminum housing, and a high temperature pancake stepper motor capable of withstanding build chamber high temperatures.

This new version of the BMG-HT allows for the distance between drive gears to be adjusted. Two screws on the side move the secondary drive gear carriage allowing to adjust the BMG-HT to more filament types and hardness.

The BMG-HT is a high temperature resistant, rigid, strong, lightweight, and good-looking extruder. BMG-HT becomes our first Professional upgrade kit that will improve reliability and performance of professional and industrial grade 3D printers.

By using our 3:1 gearing ratio, we increased the available push force and resolution although using a pancake high temperature stepper motor. The lightweight stepper motor and the Aluminum housing lead the overall weight of the print-head down. Comparing the parts replaced and added in this setup for the Intamsys Funmat HT, we lowered the weight load from above 400g to less than 260g. An over 35% weight save that will have meaningful and positive impact on the printer’s performance:

Like in all other Bondtech extruders the BMG-HT also uses our award-winning Dual Drive Gear Technology. You will experience effective and consistent extrusion no matter what material you are feeding to your printer. Our Dual Drive system will keep on going to help your Funmat HT laying down perfect layers and make your prints shine with a bright you didn’t think to be possible.

Different Funmat-HT versions come from factory with different stepper driver setups. Be sure your machine is running the extruder stepper motor at 0.7A by checking the driver DIP switches configuration.

No customer reviews for the moment.