Ultrafuse Support Layer

filament developed to be used in combination with Ultrafuse 316L e 17-4PH Metal Filaments.

Weight: 300g

Ultrafuse® Support Layer filament developed to be used in combination with Ultrafuse® Metal Filaments. When printed between support and the object, it creates a barrier during sintering and facilitates the separation of support from the metal part. Ultrafuse® Support Layer is not developed to print stand-alone parts and should be printed as a layer attached to the support structures in dual extrusion prints.

Benefits:

Ultrafuse® Support Layer is uniquely designed for FFF printing of Ultrafuse® 316L and 17-4PH filaments and prevents the support from sintering to the printed part

* A hardened, coated or ruby nozzle is recommended for printing

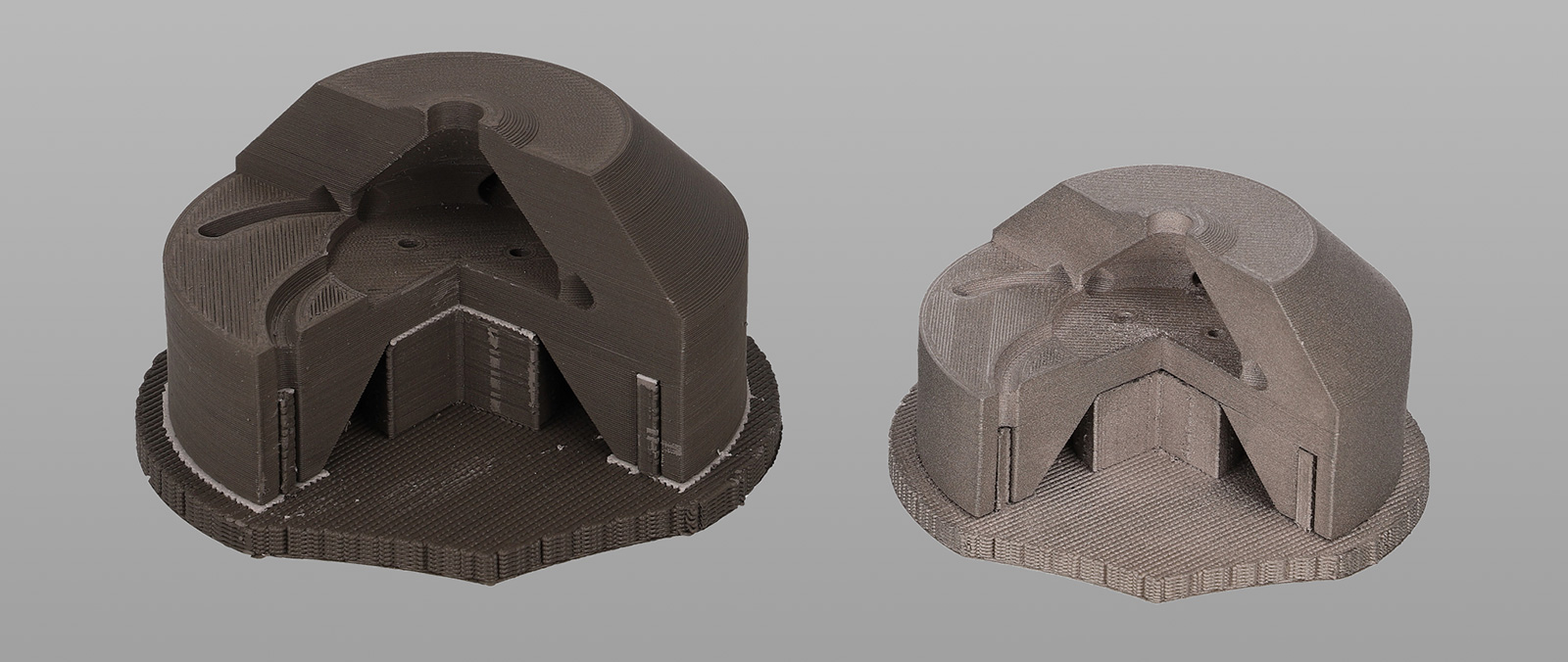

Example Applications:

*This product is intended exclusively for sales, distribution, and use within the European Union, Albania, Iceland, Liechtenstein, Monaco, North Mace- donia, Norway, San Marino, Serbia, Switzerland, Turkey, and the United Kingdom and is only available for our customers located in those countries.

| Recommended 3D-Print processing parameters | |

| Nozzle Temperature | 245 – 260 °C |

| Build Chamber Temperature | Passively heated, closed chamber |

| Bed Temperature | - |

| Bed Material | - |

| Nozzle Diameter | ≥ 0.4 mm |

| Print Speed | 15 - 20 mm/s |

| Drying Recommendations | |

| Drying recommendations to ensure printability | Ultrafuse® Support Layer is in a printable condition, drying is not necessary |

No customer reviews for the moment.