Shining3D FabWash

Smarter Post-processing

· A Consistent, Automated Workflow

· Automated Part-Release

· One Size Fits All

· Never Think About Wash Time Setting Again

· Easy To Use, Safeguards Your Workplace

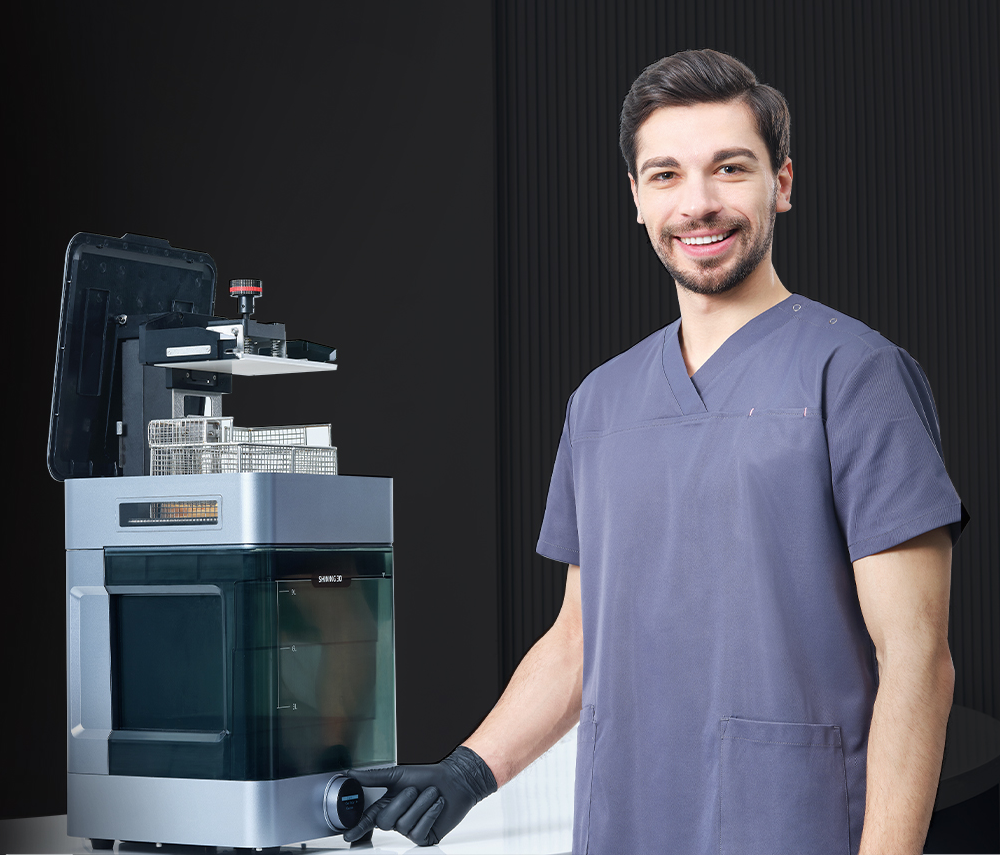

FabWash is the first fully automated, multi-stage part release, washing and drying system designed to provide the ease of use, consistency, speed, and cleanliness demanded by the modern dental 3D printing.

FabWash is pre-programmed for each material with an automatic process of part release, wash and dry. Once completes, FabWash automatically lifts parts and builds platform out of the solvent. Parts and build platform are ready when you are.

Inspired by the latest input from the dental community, FabWash is designed for instant part release, eliminating the risk of damaging parts using traditional removal tools. FabWash prepares optimal motion logic for each material to deliver a superior, hassle-free part release experience.

Handle AccuFab-L4D/L4K build platform or AccuFab-D1s build platform with the separate build platform adaptor.

Use the pre-programmed wash settings or save your own frequently used custom profiles to improve post-processing efficiency. FabWash equipped with Wi-Fi enables over-the-air updates to deploy the latest firmware and material library.

We know that one of the most precious resources in a dental clinic is time. So in addition to making FabWash run an extremely fast cycle, we made it dead simple to operate. If your staff can operate a smartphone, they can use Pro Wash/Dry with very little training. And to reduce maintenance, we sourced innovative materials that are resistant to chemicals.

Information sent through this form will be used for the provision of the requested services. I have read and ACCEPT unreservedly the Privacy policy, and I AUTHORIZE the treatment of my personal data.

| Printer Compatibility |

AccuFab-D1s, AccuFab-L4D/L4K |

| Product Weight & Dimensions |

15KG |

| Bucket Volume |

9.5L |

| Maximum Part Size |

199*124*180 mm |

| Suggested Operating Environment |

10~30℃ / 30%~70%RH |

| Suggested Transportation Environment |

-10℃~70℃ |

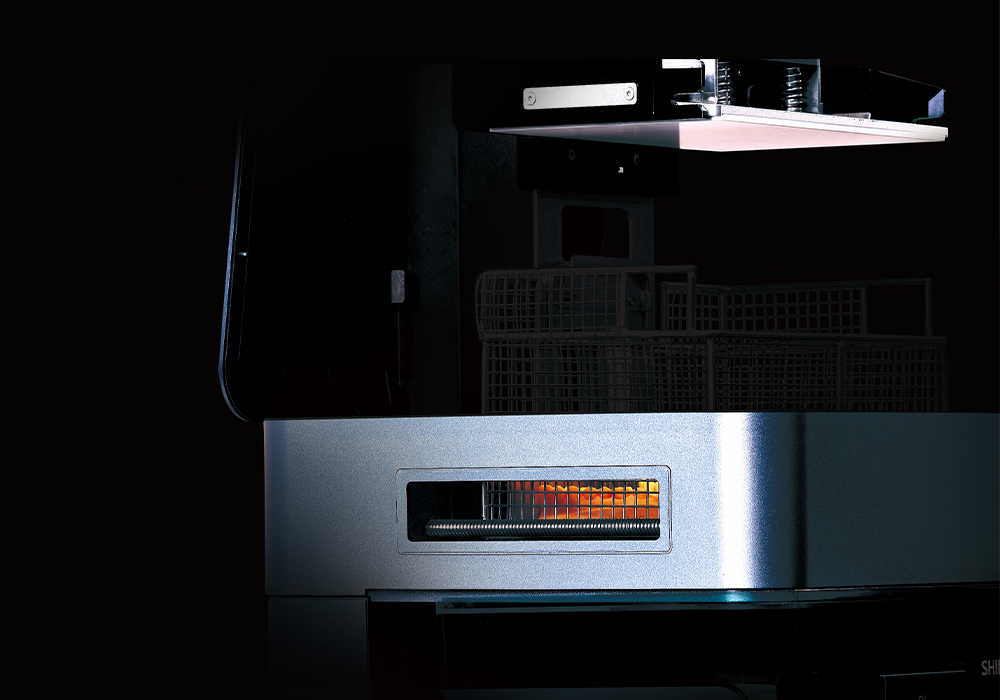

| Agitation Method |

Magnetically coupled impeller |

| Include Accessories |

Wash Bucket / Wash Basket / Scraper / Brush The adapter / Quick Guide |

| Power Requirements |

100–240 V / 2.0A 50/60 Hz |

| Compatible Solvent |

> 75% alcohol, IPA, Water |

| Connectivity |

Wi-Fi |

| User Controls |

1.54 inch OLED & Rotary knob |

| Safety Sensors |

Automatic start/stop sensors; Build platform detection sensor Solvent bucket detection sensor; Safety pressure sensor Emergency stop switch |

| Product Features |

Automatic part release function; Automatic predefined wash/dry function User programmable wash/dry option |

Write your review

No customer reviews for the moment.