CREA 3D offers training courses to professionals, companies and universities that intend to implement the various 3D printing and 3D scanning technologies within their production processes, or to deepen their knowledge of applications and materials.

ON-SITE TRAINING COURSES CALENDAR

[C0] Introduction to Additive Manufacturing

Purpose

Exploring the future of production processes through new technologies and the potential they offer in the various industrial sectors. Compare additive manufacturing with traditional manufacturing to understand its advantages.

Content summary

- State of the art

- Fundamental concepts of Additive Manufacturing

- Additive Manufacturing vs Traditional Manufacturing

- Additive Manufacturing technologies

- Potential of AM in production processes

- Economic impact on the company

- Sectors of use, applications and case studies

[C1] Materials for Additive Manufacturing

Purpose

Know the characteristics of filaments, resins and powders printable with the respective technologies. Learn more about pre- and post-processing operations, and discover applications and case studies.

Content summary

- Introduction to 3D printing technologies

- Basic polymers and engineering polymers

- Support materials

- ESD-CNT-MDT, recycled, wear-resistant and flame retardant materials

- Composite materials

- High-Temp Materials

- FDA, UL94V0, REACH, ROHS certifications

- Resins for SLA-DLP-LCD

- Washing & Curing

- Powders for SLS

- Post-processing

- Applications and case studies

[C2] Immersive Slicer Training

Purpose

Immersive training to understand and exploit the potential of the slicing software, to be able to maximize dimensional accuracy and productivity, optimize aesthetic aspects and mechanical properties.

Content summary

- Presentation of the interface

- Material configuration and printing profiles

- Using the Cloud

- Line Type of the model

- Infill settings

- Support optimization

- Print bed adhesion management

- Dual extruder printing

- Special modes

- Advanced functions: per-model settings, dual color printing, height pause

[C3] DfAM course

Purpose

Learn the fundamental concepts of design focused on product development to be created using additive technologies.

Content summary

- Why DFAM

- General rules of the DFAM

- Supports management

- Adhesion to the build plate

- Anisotropy of the part

- Part orientation

- Mechanical resistance of the part

- Ntopology for Additive Manufacturing

- Generative design and topology optimization

- Lightweighting, mass customization and aesthetic design

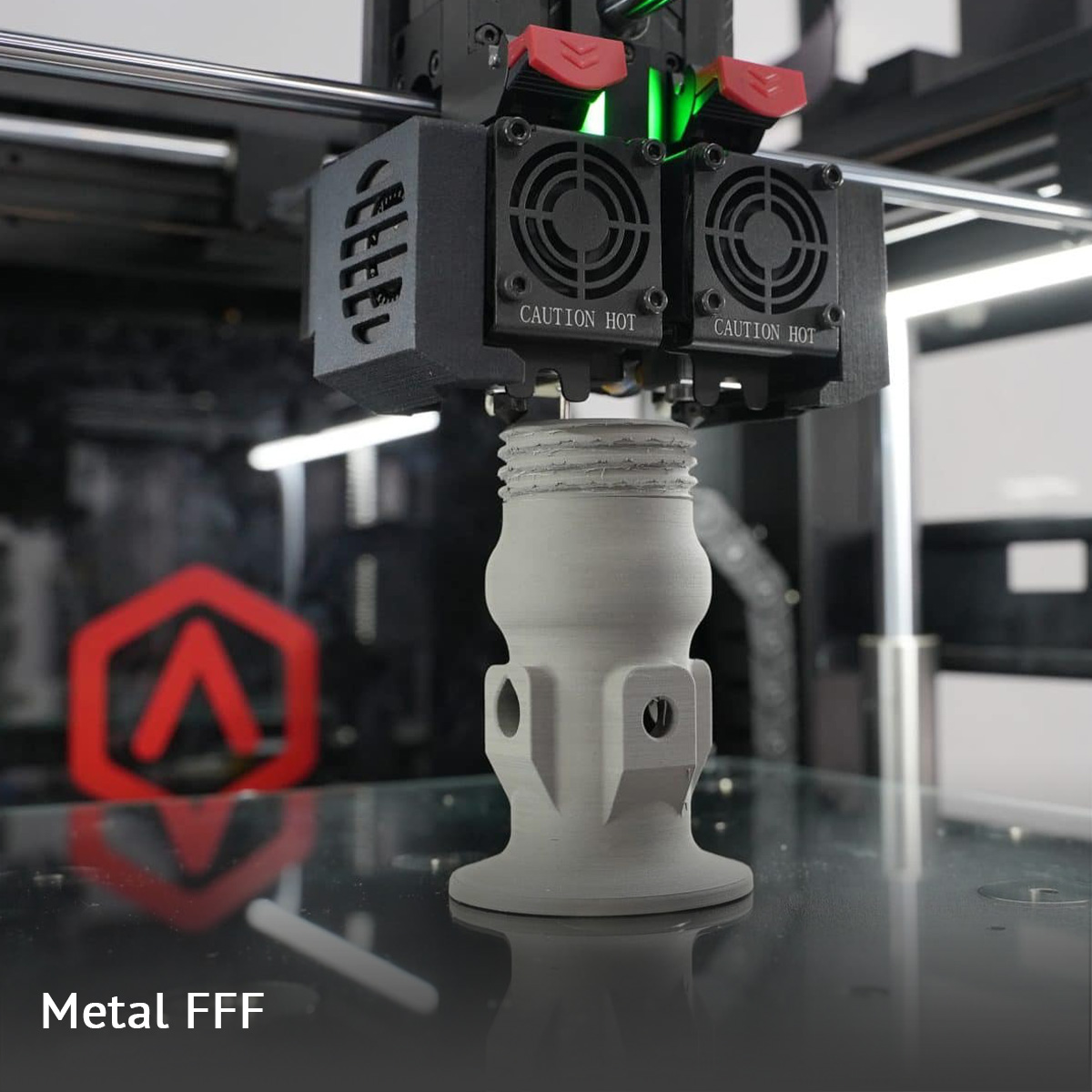

[C4] Metal FFF course

Purpose

Learn the fundamental concepts and design rules for producing parts using Metal FFF additive technology; make the most of the potential of your slicing software to maximize dimensional accuracy and productivity of the metal components that can be made and optimize aesthetic aspects and mechanical characteristics.

Content summary

- Introduction to the technology

- Why consider Metal FFF as a production process

- Design criteria for the Metal FFF

- 3D printing solutions and materials

- Influence of process parameters

- Slicing

- Lightweighting, mass customization and FEM analysis

- Post-processing, treatments and finishes

- Applications and case studies

[C5] 3D Scanning and Reverse Engineering

Purpose

Know the 3D scanning and Reverse Engineering process to analyze and reconstruct a product for which you do not have the original designs or three-dimensional modeling files, carry out a metrological comparison with the CAD model and a re-design, in order to improve its appearance and functionality .

Content summary

- General information on 3D scanning and Reverse Engineering

- How to choose a 3D scanner

- 3D scanning demo

- Mesh generation

- Post-processing

- Export .STL,.OBJ or point cloud files

- Mesh inspection

- Metrological comparison with CAD model

- Mesh reconstruction methods

- Exporting the .STEP file

[C6] Fusion 360 for Additive Manufacturing

Purpose

Learn about the new approach to innovative design through CAD-CAM software optimized for 3D printing.

Content summary

- Introduction to CAD/CAM

- Presentation of the interface

- Work areas

- Project area

- Creating a project

- Solid modeling

- 2D environment

- 3D environment

- Hints on creating an Assembly

- Hints on parametric modeling

- Saving and exporting .STP, .STL formats

[C7] nTop for the design of the future

Purpose

Explore the potential of the implicit modeling software nTopology, in order to generate unique designs for Additive Manufacturing obtained through topology optimization, surface textures and lattice filling structures.

Content summary

- nTop for Additive Manufacturing: implicit modeling

- nTop's automated design process: field driven design

- Lightweighting techniques: topological optimization, lattice structures,

conformal ribbing, texturing - Examples of mass customization, aesthetic design and tooling design

- FEA/FEM Simulation

MORE INFORMATION