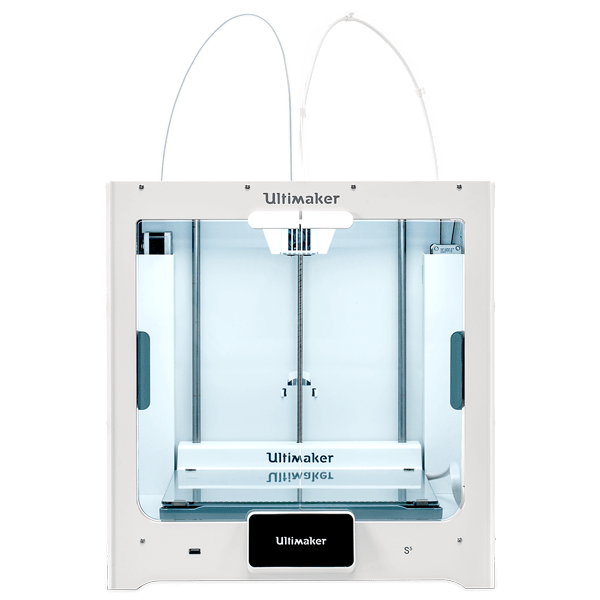

Ultimaker S5

Powerful, reliable, versatile 3D printing

- The complete solution for 3D printing

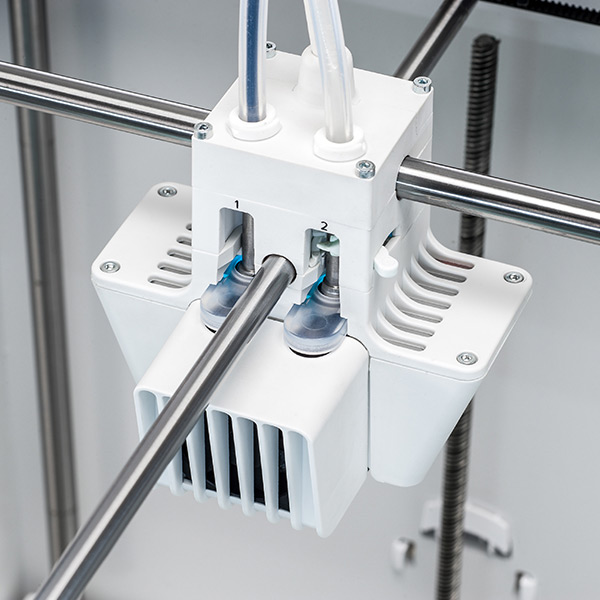

- Double extruder, reliable, precise and easy to use

- Freedom in the choice of proprietary or third parties materials

- Free Ultimaker Cura software, chosen by over 2 million users

- Swappable Print Cores in a few seconds

- 3D Printing prototypes and functional parts with composite materials

€ 5.495 IVA escl.

Key features

Enhanced reliability

Active bed leveling ensures a perfect first layer, a closed front controls airflow, and a filament flow sensor will pause your print and notify you if you run out of material. Trust the S5 to do its job while you do yours.

Bigger build volume

A build volume of 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches) gives even more freedom to realize your designs or print multiple parts in one go, so you can meet demand with maximum efficiency, while fitting comfortably on your desk.

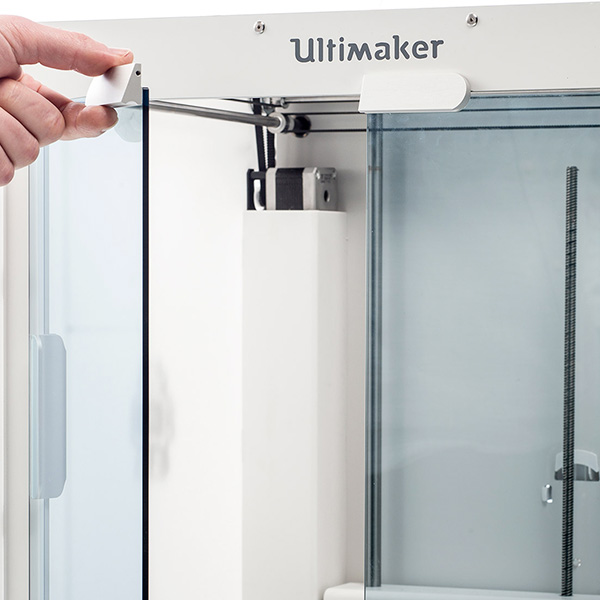

Fast setup, high uptime

With Ultimaker’s unique print core design, swap nozzles in seconds to switch between build and support materials, or choose from 0.8, 0.4, or 0.25 mm print cores for fast or detailed prints.

Easy touch control

A 4.7-inch (11.9 cm) touch display makes operating the 3D printer effortless, displaying visual guides to explain configuration changes and maintenance, plus a visual preview of your print.

Ultimaker Material Alliance Program

To meet global demand for industrial-grade engineering 3D printing materials, Ultimaker started the Ultimaker Material Alliance Program, that has now influenced over 80 companies worldwide to develop material print profiles for FFF 3D printing.

Complex prints made easy

Water-soluble supports

Create intricate geometries and technical models by combining your build material with water-soluble PVA support material, then remove supports by simply resting the print in water.

Ultimaker 3D printers are the most reliable dual extrusion machines on the market.

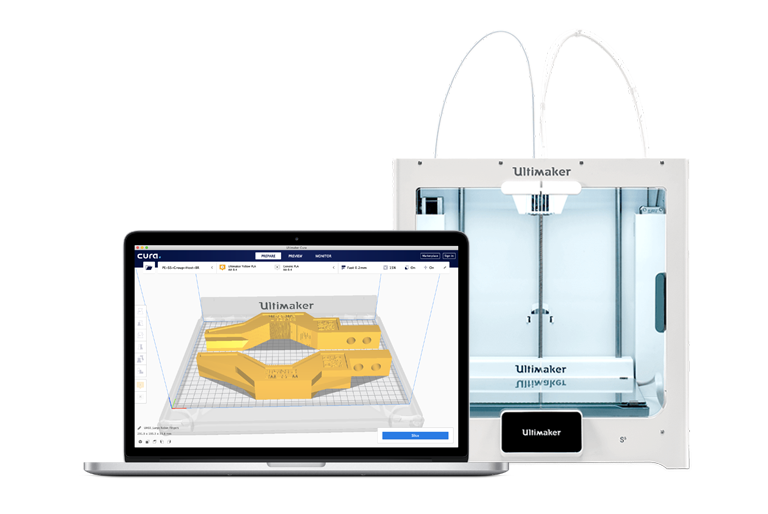

Ultimaker Cura Software

Ultimaker Cura prepares your model for 3D printing. Optimized, expert-tested profiles for 3D printers and materials mean you can start printing reliably in no time. And with industry-standard software integration, you can streamline your workflow for maximum efficiency.

Trusted by

Reinventing Manufacturing with Ultimaker S5

Ford: jigs, tools, and fixtures for manufacturing process

Ford’s employees use a lot of custom tools during their vehicles’ production. These are often designed for one specific task and model. The creation of these tools externally takes a lot of time and is very expensive. To get tools faster, the team at Ford decided to pilot 3D printing as a possible solution.

Heineken: Ensuring Production Continuity With 3D Printing

With over 150 breweries around the world, Heineken is one of the largest global producers of beer. One brewery in Seville, Spain, produces famous brands such as Cruzcampo, Desperados, Heineken, and Amstel. The beer is brewed, packed, and then shipped throughout Spain and beyond. Packaging Manager, Juan Padilla González has implemented 3D printing to increase uptime and efficiency at the Seville brewery.

MORE INFORMATION