In addition to providing Design and Reverse Engineering Services through the FastParts division, the Crea3D team supports companies in choosing and configuring the most suitable production systems for each sector of activity.

For all companies wishing to enter the world of additive manufacturing, or for those ready to convert their traditional systems into new automation and corporate interconnection processes, Crea3D offers pre-configured and modular production systems.

Why an additive manufacturing system

What is a Print Farm?

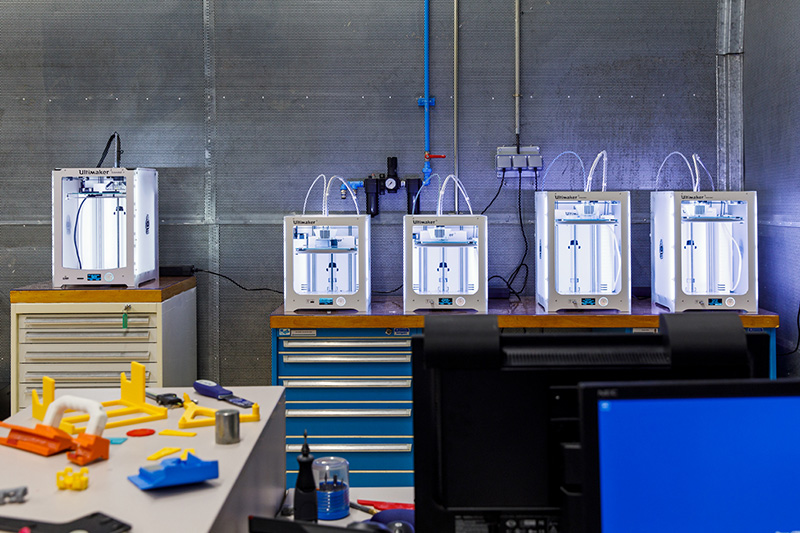

Having a series of 3D printers available allows you to manage mass production or optimize the rapid prototyping flow. The configuration of multiple 3D printers is essential to further reduce production times and costs.

And besides, if those 3D printers are all connected to the network, it is possible to launch and remotely monitor production processes, by optimizing procedures.

Photo: Ecole Militaires de Bourges (EMB) (France), setup of 50 Ultimaker 3D printers

Ultimaker Digital Factory

See an overview of printers and print jobs, manage and share your 3D printers among teams within your business, start 3D printing from anywhere in the world and schedule maintenance sending reminders when operations are needed.

For Ultimaker 2+ Connect, Ultimaker S3, Ultimaker S5 e Ultimaker S5 Pro Bundle.

Plus, Ultimaker Enterprise Software empowers your teams to scale 3D printing innovation across your organization, with a subscription plan for every need.

EXAMPLES OF PRODUCTION SYSTEMS WITH ULTIMAKER 3D PRINTERS

Eriks

(Industrial components)

Initial savings of €350.000

Volkswagen Autoeuropa

(Automotive)

-91% costs | -95% time

Jabil Auburn Hills

(Services)

-30% costs | -80% time

Owens Cornings

(Chemical industry)

17.000 hrs of printing in a year, for product tests

Make Architects

(Architecture)

-90% costs | -90% time

Duke University

(Education and Research)

Over 3.500 parts per month

Customized solutions and installations

After evaluating the most suitable solution, our specialized technicians will take care of the delivery and installation of the system, including the configuration of the network. In addition, there will be a training day that enables operators to use the installed printers correctly.

Fill in the form below to receive further information.