PETG Magneto Detectable for the Food&Beverage Industry

Detecting foreign matter during food processing and packaging plays a fundamental role in guaranteeing safety and quality of products, excluding contamination and the presence of plastic in food products.

To meet this need, Crea3D® has included in its range a material detectable by metal detectors, specifically designed for use in the food industry: PETG MDT, printable with any FFF 3D printer.

PETG MDT is produced by adding a detectable additive thanks to which, in the event that a plastic component breaks during production, any fragment, even the smallest one, can be quickly detected using a standard metal detector placed at a specific point in the production line.

Minimizing the risk of contamination by foreign matter in environments where cleaning, hygiene and safety are essential requirements, makes PETG MDT particularly suitable for the food industry, where the absence of contaminants of any origin is essential.

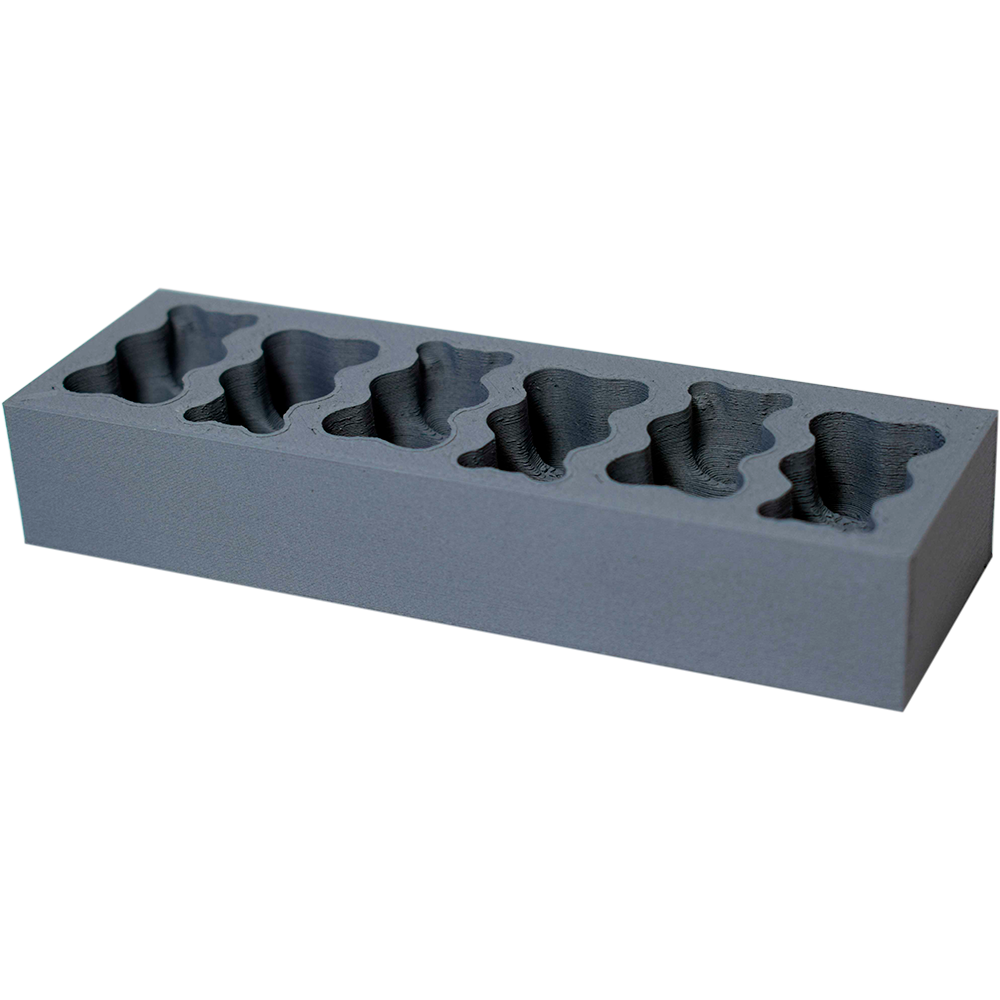

PETG MDT is also recommended for the manufacture of sensors, intelligent packaging, molds, conveyors, etc.

Furthermore, this filament has a high dimensional stability, typical of PETG based materials and it's very simple to print at temperatures between 220 °C and 240 °C, preferably with steel nozzles or with a ruby tip (ideal for abrasive materials ) and print bed around 85 °C. Among other features, the material, which is not hygroscopic, resists humidity, fungi and mould.

The advantages in terms of weight must also be considered since many components of plants and equipment used to produce and pack food are conventionally made of metal. They can therefore be replaced with PETG MDT which has a density of 1.57 g/cm³ and this leads to a considerable decrease in weight.

The fields of application are numerous and different, from the dairy industry to the meat processing, up to the baking sector. In each of these areas, the greater safety and weight reduction resulting from the use of these materials means a tangible saving of energy and costs.

Do you want to discover further applications in the food&beverage industry? Do you want to develop new ones?

In Same Category

Related by Tags

- Krones: Optimized 3D-printed parts & spares for customers anywhere

- 3D printing for the production of sheet metal bending dies

- Bambu Lab X1E: multifilament 3D printing in industrial applications

- 3D printing for the Education and STEM disciplines: the FabLab Poliba experience

- 3D printing and footwear: the FuSa shoe

Leave your comment