KIMYA publishes the results from the Life Cycle Analysis for its 3D filaments

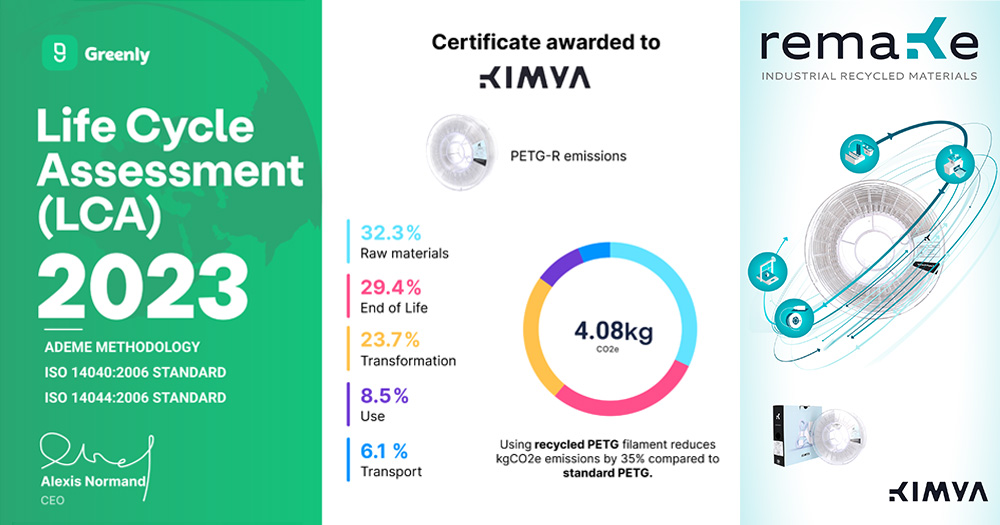

In order to provide users with even more transparency, KIMYA, an ARMOR GROUP company, published the Life Cycle Analysis (LCA) for its 3D PETG filaments, in January 2023. The conclusion: using recycled PETG filaments helps to reduce CO2 emissions by 35% compared with standard PETG. As a pioneer in the development of eco-designed 3D materials, KIMYA hopes to encourage users to give priority to recycled filaments in the interests of sustainability and resource conservation.

A reduction of 35% CO2 emissions by using Kimya’s PETG recycled filaments

Life Cycle Analysis (LCA) is a multi-stage, multi-criteria analysis that measures the environmental impacts generated by a product or service throughout its life cycle: from the extraction of raw materials to the end of life, including manufacturing and use. Conducted in collaboration with Greenly and based on ADEME guidelines, the LCA of Kimya’s recycled PETG 3D filament shows an emission of 4.08 kgCO2 versus 6.27 kgCO2 for Kimya standard PETG filament. Using recycled filament helps to reduce emissions by 35% when compared with the standard version.

“Born out of our company’s DNA and a strong demand from our distributors, the Life Cycle Analysis, carried out on our standard and recycled PETG filaments, makes it possible to provide users with transparent information on the environmental impact of the materials they use, in order to encourage them to choose more environmentally friendly alternatives” explains Benoît Stoeux, Managing Director of KIMYA

“Our LCA approach is part of our ongoing commitment to more sustainable production as evidenced by our “Remake” line of recycled filaments that we are continuing to expand to meet everyone's needs. At the same time, we are also thinking about our packaging, which is now 100% environmentally friendly, using recycled cardboard and soluble ink. Not to mention the mounting flanges for our 3D filament spools, which are now made of 95% recycled polycarbonate. The next step for KIMYA is to conduct a full carbon assessment of our business in order to accurately quantify our carbon footprint and undertake specific measures to reduce our CO2 emissions” concludes Benoît Stoeux.

Discover the KIMYA filament portfolio and the Remake range.

Producing fairly, without wasting resources thanks to 3D printing

According to Sculpteo's “The State of 3D Printing” 2022 edition, additive manufacturing improves the environmental impact of activities of the users who were interviewed (managers, engineers, designers): 41% say additive manufacturing helps companies meet their sustainability goals, and 61% of manufacturers believe the technology allows them to produce in the right quantities for their needs.

“Born out of the determination of the ARMOR GROUP to turn waste into a genuine resource, KIMYA entered the additive manufacturing market in 2016 by offering its first filament designed using industrial waste from food packaging. At KIMYA, we are convinced that 3D printing is a technology that can produce as close as possible to customer needs, without wasting resources” continues Benoît Stoeux.

ARMOR GROUP, a company that is committed

For ARMOR GROUP and KIMYA, social responsibility is the result of a collective and constantly evolving process. Through its activities, the group strives to stimulate the drivers of sustainable growth. As a solid and trusted industrial partner, ARMOR GROUP is pursuing its development with the same objective: to be useful to society in order to successfully meet the challenge of transition.

“Aware of the responsibilities placed upon us, we at ARMOR GROUP act according to a clear strategic line, respectful of the environment and giving a central place to the women and men of the company, as evidenced by our EcoVadis gold medal. Our commitment to innovation in the social arena is shared by all of the group's activities, which are driven by the same vision: investing for the future” concludes Annabelle Guillet, Director of Societal Innovation at ARMOR GROUP.

Leave your comment