INTAMSYS 3D printers: the affordable solution for 3D printing PEEK and high performance polymers

Crea 3D is pleased to announce the new collaboration with INTAMSYS (INTelligent Additive Manufacturing SYStems), the manufacturer of industrial-grade 3D printers designed for printing high-performance polymers.

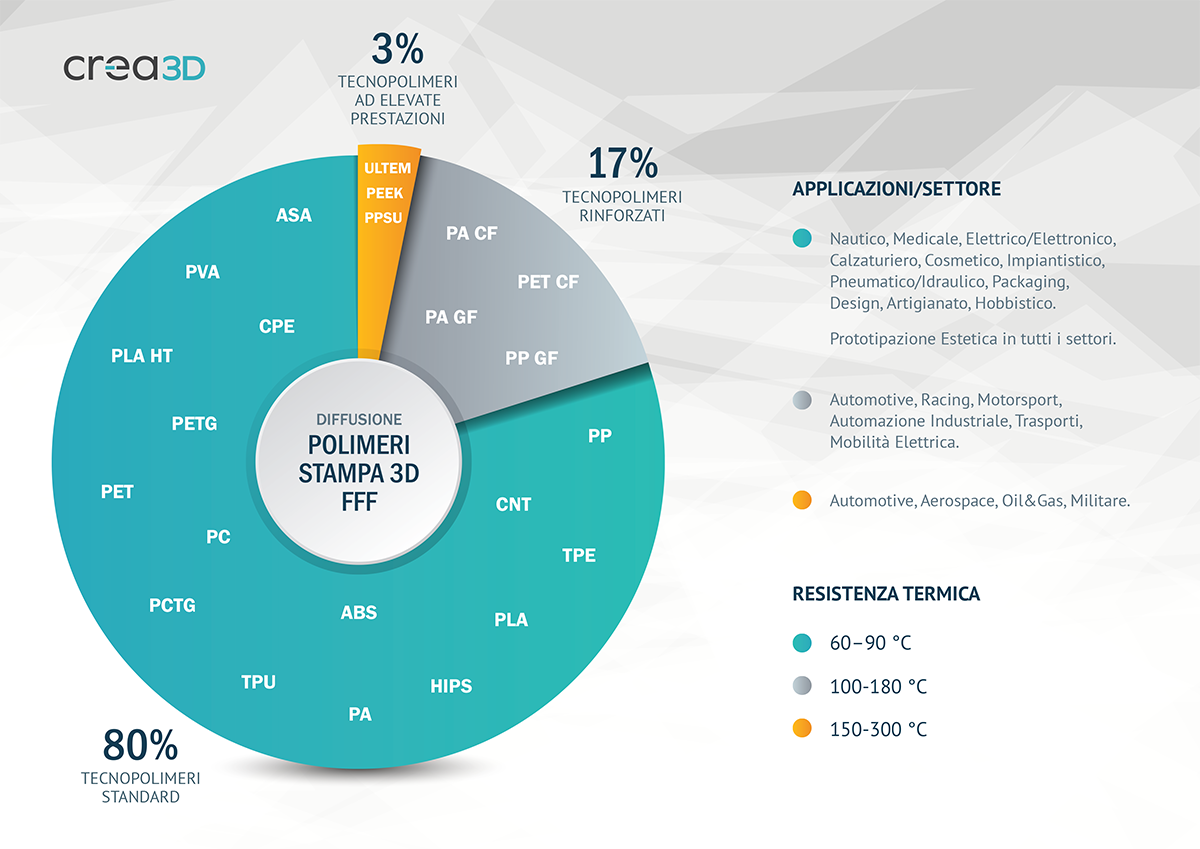

In the very vast panorama of 3D printing applications and available materials, surely some polymers are used more than others.

From the plastics generally called "standard" for the most common applications (prototypes, jigs&fixtures, small productions), to enriched or reinforced materials, with thermal and mechanical properties that allow ever more specific applications.

The latter (reinforced materials) in particular register a significant increase in requests, thanks also to the numerous producers of plastic materials that contribute to enriching the range of possible applications.

Diffusion of technopolymers. CREA 3D survey.

There is also a growing interest in high performance polymers, used for printing parts that should operate in critical situations (high temperatures, radiation, high stress). But their use is generally limited by operating costs and processing difficulties.

In this exact sector INTAMSYS 3D printers express their "accessible" potential.

The 3D printers of the FUNMAT series, in particular the FUNMAT PRO 410 model, have a heated closed chamber and nozzles that reach high temperatures, designed to allow also the printing of technopolymers such as PEEK, ULTEM and PPSU, notoriously difficult to print with the most common desktop machines.

FUNMAT PRO 410

With the inclusion of the Intamsys brand, Crea 3D aims to enrich and complete the already varied portfolio of solutions regarding FFF 3D printing.

For more information, contact us.

In Same Category

Related by Tags

- Fireproof additive manufacturing: the benefits of flame retardant materials in modern industry

- Raise3D Announces the Launch of the DF2 Solution at Formnext

- Una self-balancing board stampata in 3D

- Nissan implements 3D printed tools, jigs and devices in its assembly lines

- ABIGO Medical and INTAMSYS - Reverse Engineering and 3D Printing

Leave your comment