Bambu Lab X1E: multifilament 3D printing in industrial applications

In recent times, the world of 3D printing has been experiencing exponential growth in the development and implementation of state-of-the-art technologies, which provide access to ever broader fields of application, as well as increasingly driven automation and process control. This phenomenon is amplified by the growth of competition, which is driving more and more manufacturers to innovate and develop new solutions to keep up with the times.

Bambu Lab has brought a high degree of innovation, developing high-performance printers while maintaining competitive prices. Given the great success of the machines developed, to raise the bar even further, it has developed a printer suitable for professional environments that can safely handle technical materials. We are talking about the Bambu Lab X1E.

Bambu Lab X1E

The Bambu Lab X1E is the evolution of the Bambu Lab X1C, made higher performing and safer by adopting upgrades that enable the fabrication of functional components through the use of materials such as PPA-CF/GF, PPS, PPS-CF/GF that was not possible to print with the manufacturer's other machines. In particular:

- An air filtration system was introduced by combining a G3 prefilter, a HEPA H12 filter, and an activated carbon filter for reduced odor and particulate dispersion during printing;

- The presence of a print chamber heated up to 60°C allows for improved print quality of technical materials prone to warping such as ABS and PC;

- Hardened steel nozzle can work up to 320°C temperature making it possible to print high-performance materials.

- Addition of an Ethernet port in addition to the 'introduction of WPA2-Enterprise Wi-Fi authentication (EAP-PEAP/EAP-TLS/EAP-TTLS) and individual physical kill switch for both Wi-Fi and Ethernet, enabling strict network security requirements to be met.

The features just mentioned add value to the excellent attributes that already constituted the X1C, such as:

- Max printing speed of 500mm/s and max extruder acceleration of 20000 mm/s2;

- Automatic multi-material handling using the AMS (Automatic Material System): up to 16 different materials;

- Automatic bed leveling and vibration compensation for better print quality even at high speeds;

- Real-time print monitoring and flow calibration by micro Lidar system.

Why Bambu Lab?

The Bambu Lab X1E makes it possible through its ecosystem to arrive at the finished product in an easy way, as the proprietary Bambu Studio slicer, with an essential and effective interface, allows you to manage the thousands of possibilities that this printer has to offer. It is possible to manage the materials loaded into the AMS system with automatic synchronization (in the case of proprietary filaments), and through simple tools in the slicer it is possible to indicate which parts of the same component should be produced with one filament rather than another.

Bambu Lab materials feature pre-set printing profiles so that you don't have to worry about basic parameters such as temperature, speed and flow.

Continuous monitoring during printing, particularly the scanning of the first layer by the Lidar sensor and the 1920x1080 camera for the rest of the print, allows for autonomous interruption of the print in case of errors. This procedure avoids material waste and limits control by the operator, who also has the option of managing it all via mobile device apps.

The Bambu Lab X1E, moreover, is equipped with AI that can detect imperfections in the first layer and errors such as filament tangles, allowing further machine failures to be avoided.

Multifilament printing in industrial applications

We have seen how the latest generation of printers such as the Bambu Lab X1E offer the ability to automatically print components composed of different materials or otherwise of the same material but with different colors. This function opens up a range of possibilities and fields of application. One of these is the industrial field, for which the use of multifilament components can bring advantages in terms of efficiency and functionality, especially because of the impact that color has in visual terms.

We provide a few examples that could give interesting insights into the application of these technologies in the industrial field:

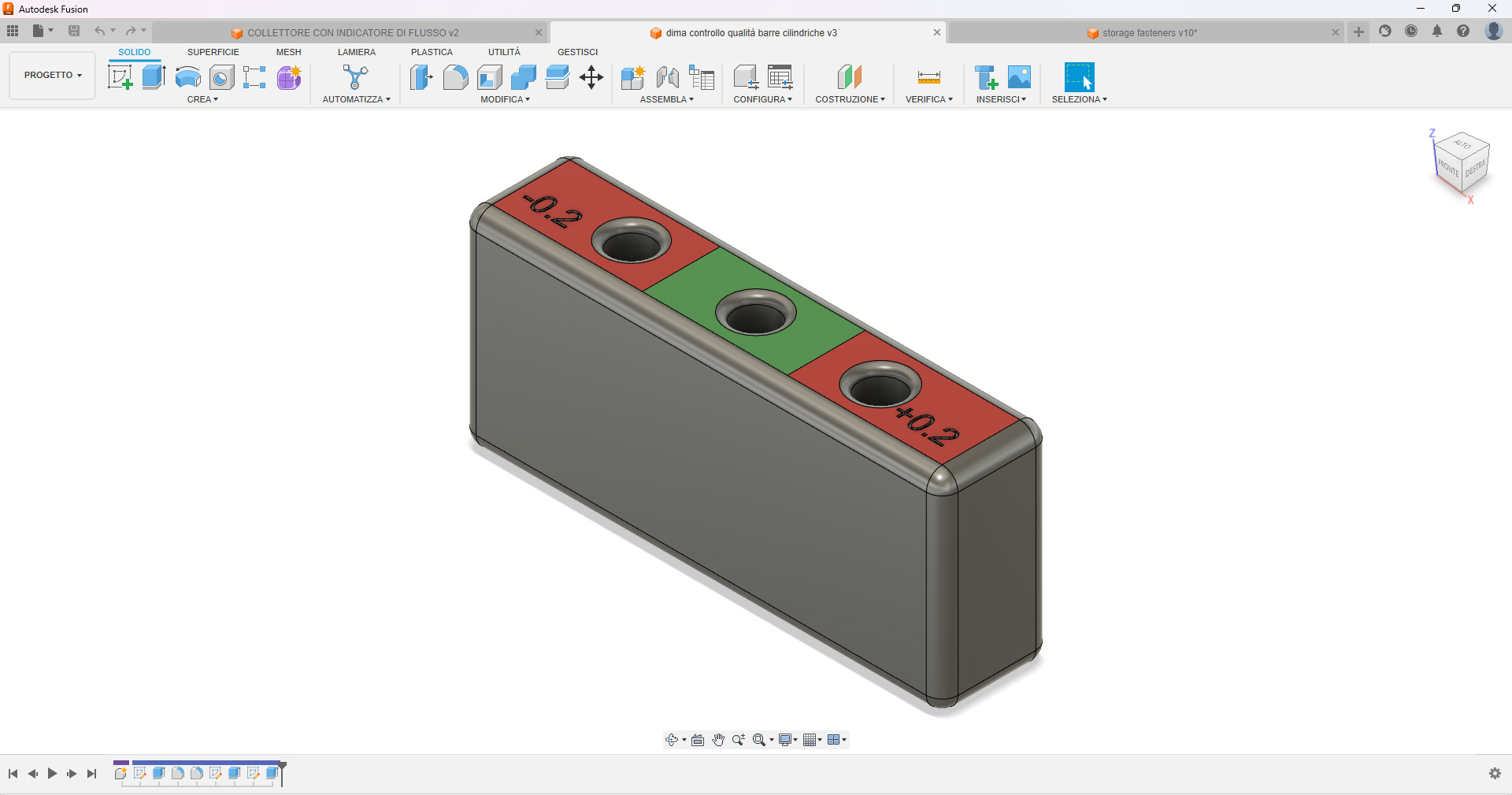

1. Quality control jigs that with colored indicators allow quickly and efficiently to verify the success of a manufactured item from a dimensional point of view. The use of these accessories makes it possible to ensure consistency of measurements and thus high quality standards while contributing in saving resources and time;

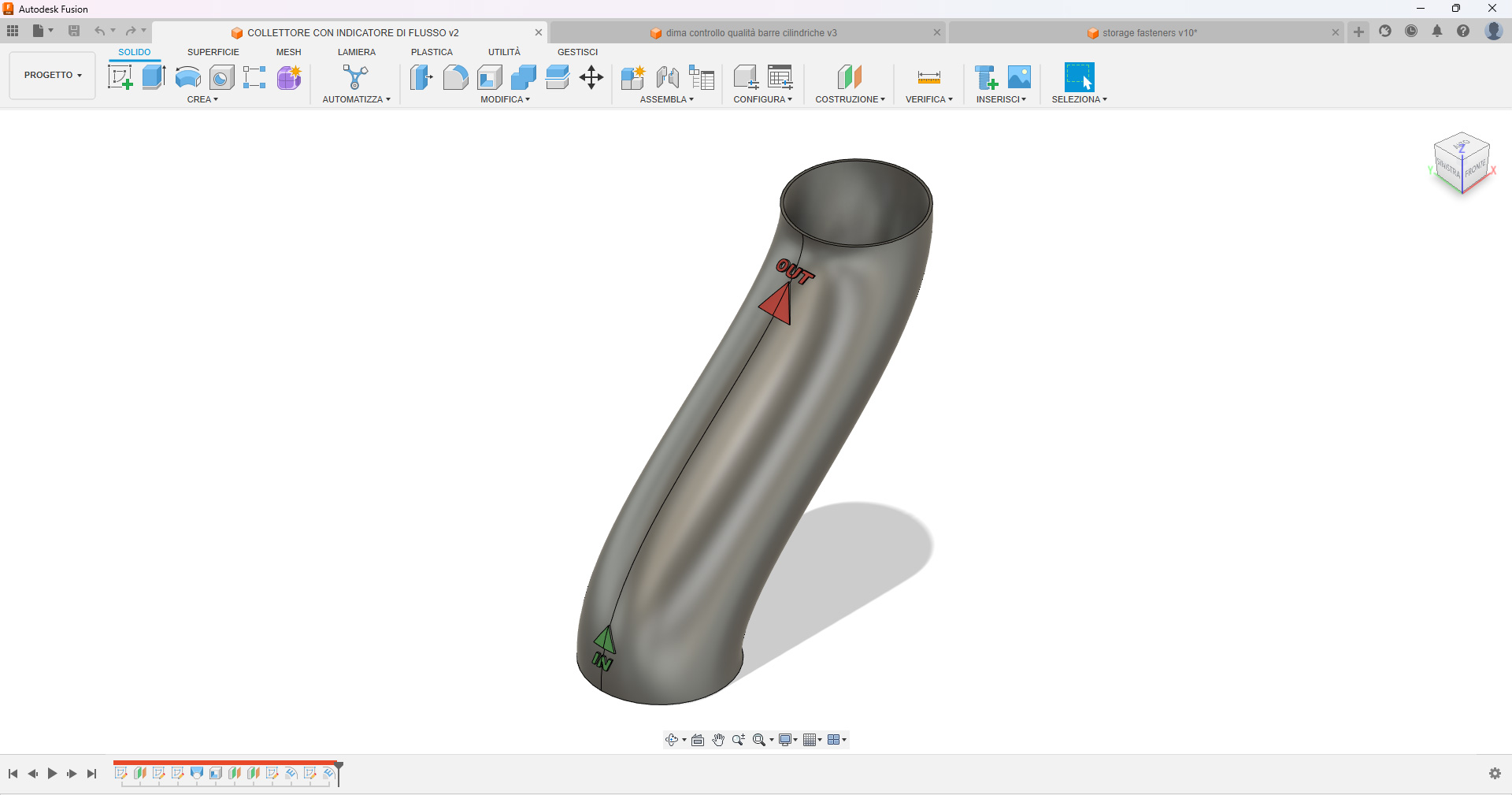

2. Components with similar features not recognizable to the naked eye that, through colored indications printed directly on the part, give the possibility of correctly performing the assembly avoiding misunderstandings. This type of application then becomes functional as it acts as an intuitive guide to assembly drastically reducing the possibility of errors in assembly by increasing the efficiency of the overall assembly process;

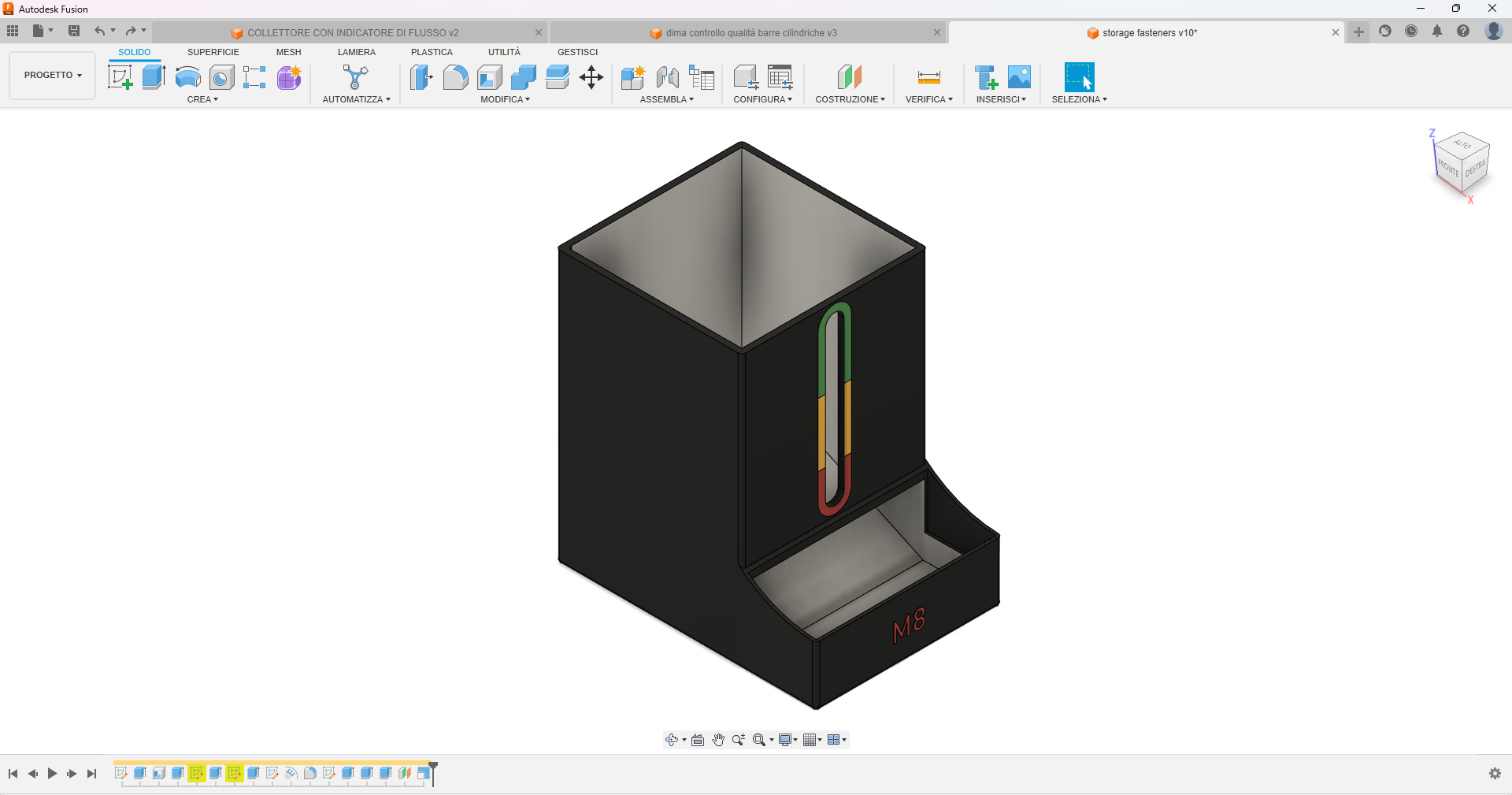

3. Containers with the presence of color bands that provide immediate visual recognition of the fill level. The presence of colored bands becomes impactful in that it allows the fill level of the container to be monitored without having to open it, giving immediate indications that allow the scheduling of a refill of consumer goods to be organized.

Workflow

CAD design can be performed with a multitude of software that can create 3-D models of objects and structures, allowing custom parts to be created based on the functionality of the object itself.

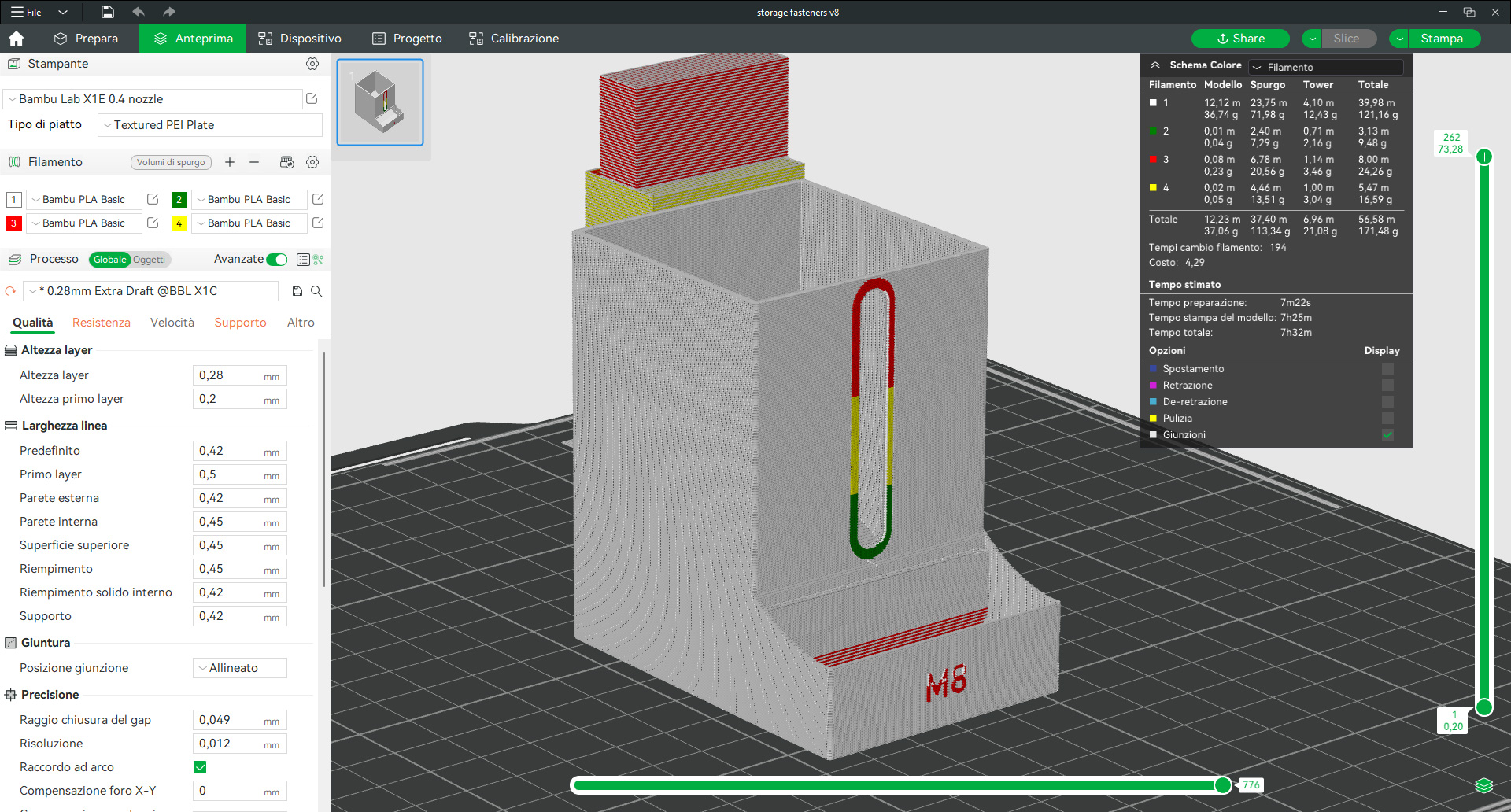

The slicing part was performed in Bambu Lab's proprietary slicer, namely Bambu Studio where we have the ability to perform a multitude of operations.

The slicer interface is organized to make it intuitive to use. It allows us to specify the type of printer, nozzle diameter, and type of printing plane, and it is synchronized with the AMS unit to recognize loaded filaments by correcting their printing parameters. It includes subdivisions for quality, strength, etc., and offers presets for different needs. It offers commands to orient the model, draw seams, color and choose filament type for specific parts of the model, and manually manage areas that need support.

In the "color painting" section, you can select the type of filament to be applied to a particular part of the same object based on availability in the AMS system and choose the type of editing tool. After choosing the printing parameters and editing the object, you can proceed with the slicing operation that converts the entire set of options you select to a G-CODE file for the printer.

The machine initializes printing through nozzle cleaning and a series of calibrations. During printing, the material change phase includes cutting, shrinking, inserting, purging the previous filament, and creating a layer on the Prime Tower to remove residue and setting up the flow of the new filament.

It is important to note that filament change operations can significantly increase printing times. Therefore, for small objects to be produced in large quantities, it is advisable to print them in a single session to reduce time and material waste.

When printed, the proposed objects are already functional, without the need for post-production. The simplicity combined with the speed of the operations to be performed to arrive at a good quality product makes the Bambu Lab X1E an excellent choice for professional applications.

The proposed examples were produced using a Bambu Lab X1C, since their purpose is purely demonstrative, and they were made in simple PLA that does not require such high-level performance as for parts made with Bambu Lab X1E. However, in the professional field, it is important to ensure a safe and pollutant-free working environment as well as performance suitable for technical materials for a wider range of applications, which makes Bambu Lab X1E the most suitable choice for working rather than hobbyist environments.

In Same Category

Related by Tags

- Krones: Optimized 3D-printed parts & spares for customers anywhere

- 3D printing for the production of sheet metal bending dies

- Bambu Lab X1E: multifilament 3D printing in industrial applications

- 3D printing for the Education and STEM disciplines: the FabLab Poliba experience

- 3D printing and footwear: the FuSa shoe

Leave your comment