3D printing and footwear: the FuSa shoe

We have recently addressed the topic of 3D printed footwear, focusing on the advantages of FFF technology applied to this type of processing.

Guided by the usual desire for experimentation and the will to keep innovating, Crea3D and FastParts teams have decided to join forces to give birth to a real product.

We commissioned the designer Fabrizio De Lucia to model a sports shoe, entirely designed to be 3D printed.

Fabrizio specializes in modeling footwear (and more!) through augmented reality and Gravity Sketch software.

--- Gravity Sketch is also ideal for the Education sector –

So, from Fused Filament Fabrication technology and Sapato ("shoe" in Portuguese) FuSa was born, the customized 3D printed shoe.

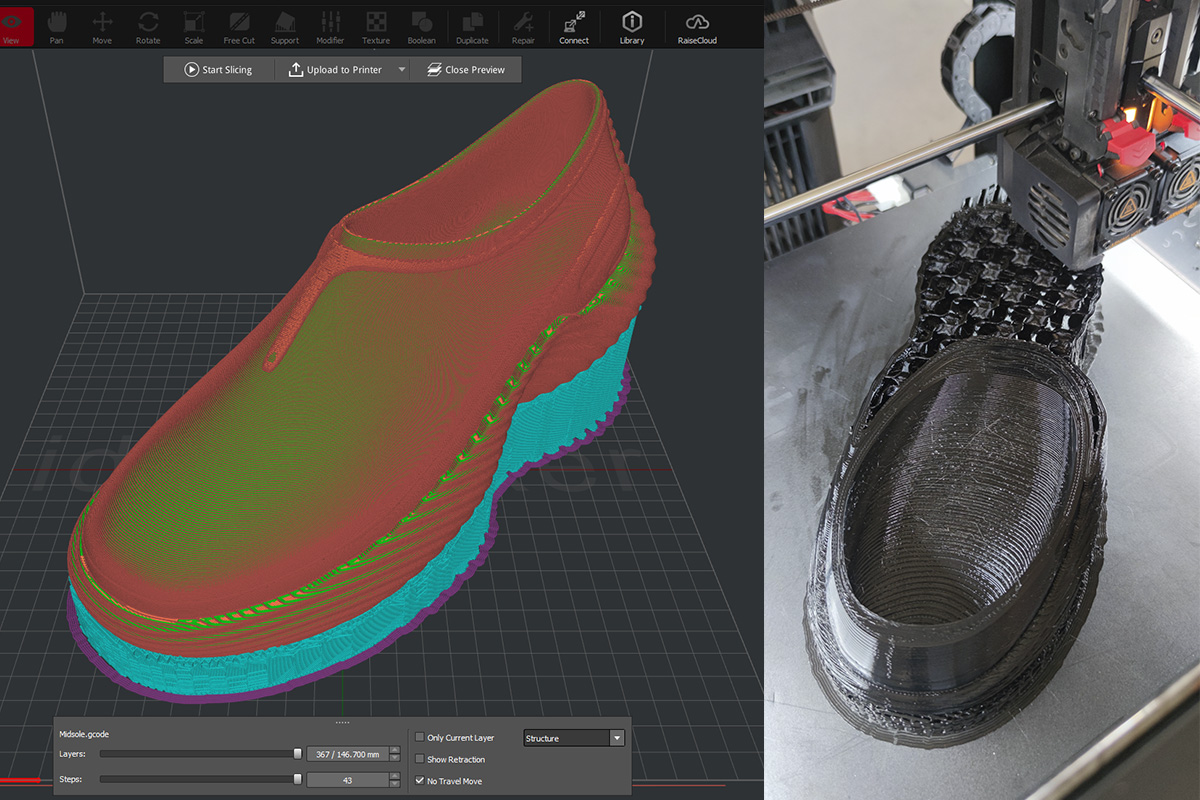

After generating numerous variants, we entrusted the final project to Fastparts, who chose the most suitable material (TPU), optimized the ideaMaker slicing parameters, and used the Raise3D Pro3 3D printer for the creation of the first prototype.

The result is definitely positive, a smooth 3D printing and a fairly light product, ready to be worn.

But we are still in the initial stages of this new workflow.

Next steps:

- Reduce the printing time to less than 24h

- Use a recycled TPU

- Further optimize the printing parameters

- Using less material to achieve a weight of less than 500g

Are you ready to take a step into the future? Contact us for more information.

Leave your comment