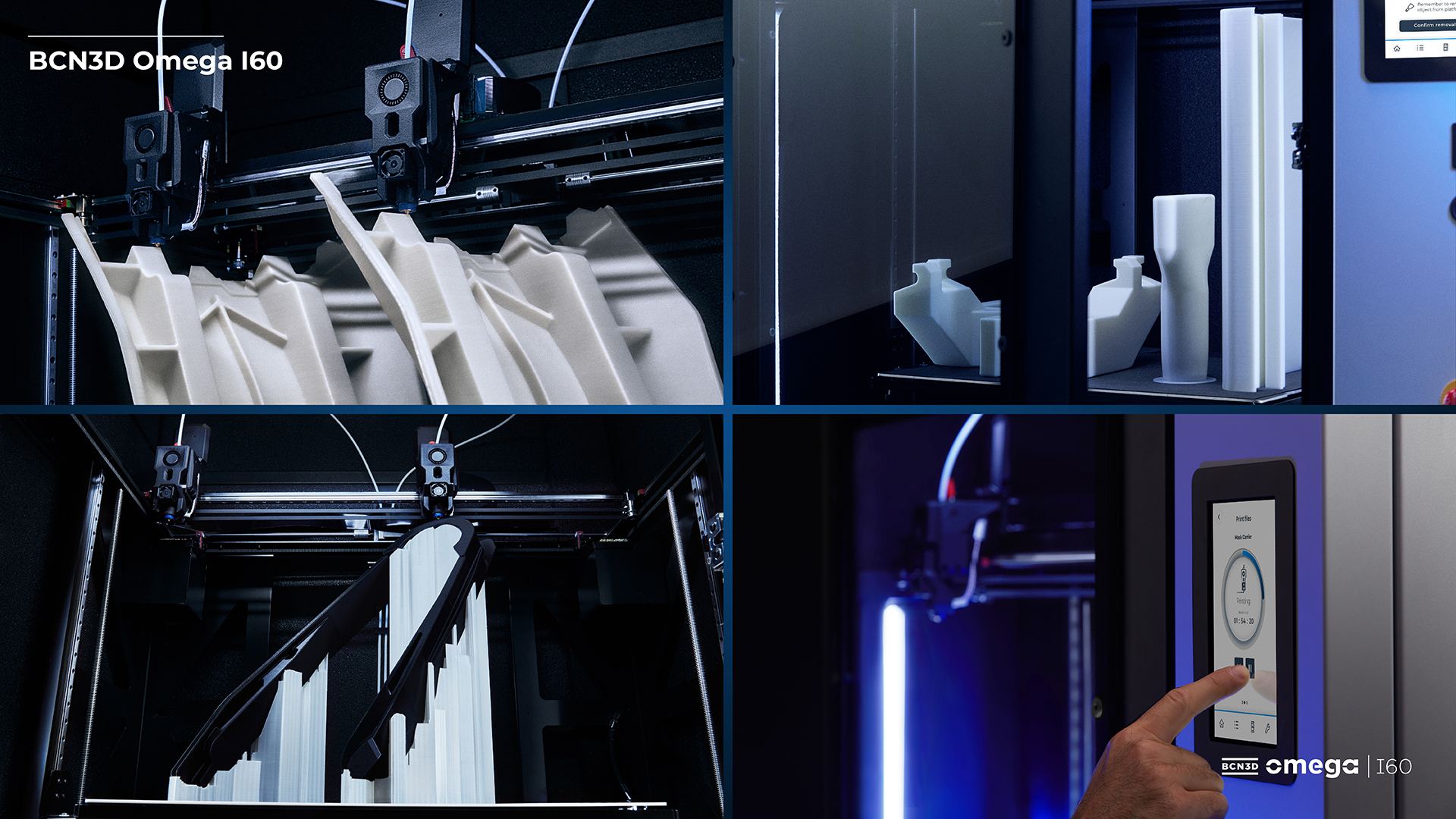

BCN3D Omega I60 is a high-speed industrial 3D Printer built for the factory floor designed specifically to produce large-scale, strong tooling, jigs, and fixtures.

BCN3D Omega I60 is a high-speed industrial 3D Printer built for the factory floor designed specifically to produce large-scale, strong tooling, jigs, and fixtures. It features BCN3D’s signature IDEX technology, a massive print volume of 60L, a heated chamber of 70ºC, a temperature and humidity-controlled material operations system, and a direct-drive high-speed extruder that reaches up to 300 mm/s.

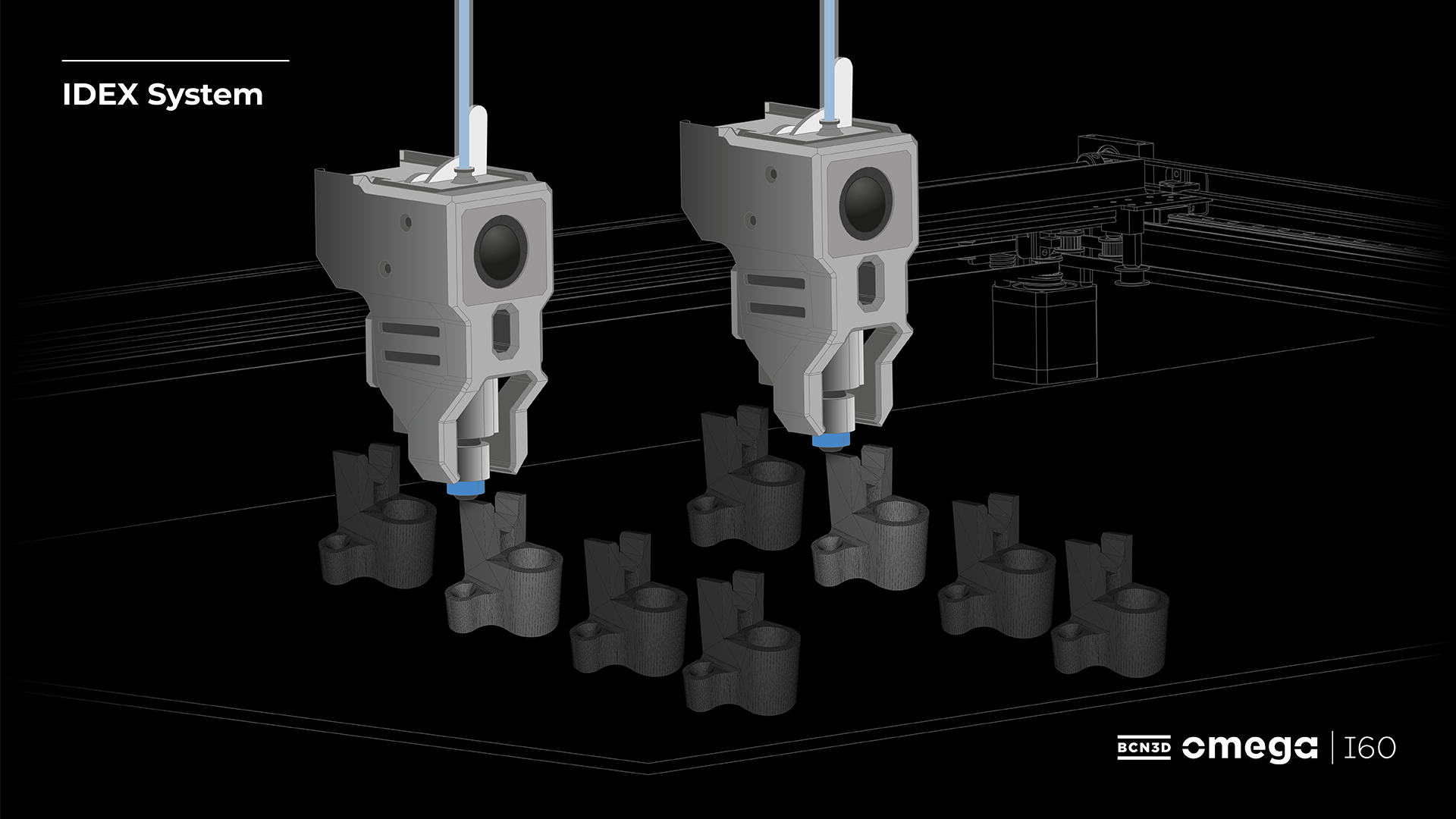

IDEX stands out as the sole extrusion system with the unique capability of printing using two independent heads. Users can double productivity with duplication and mirror modes or produce parts with support without cross-contamination. BCN3D Omega I60 is equipped with a refined IDEX technology, where the X motors remain stationary during the printing process. This design feature minimizes inertia, resulting in accelerated print speeds.

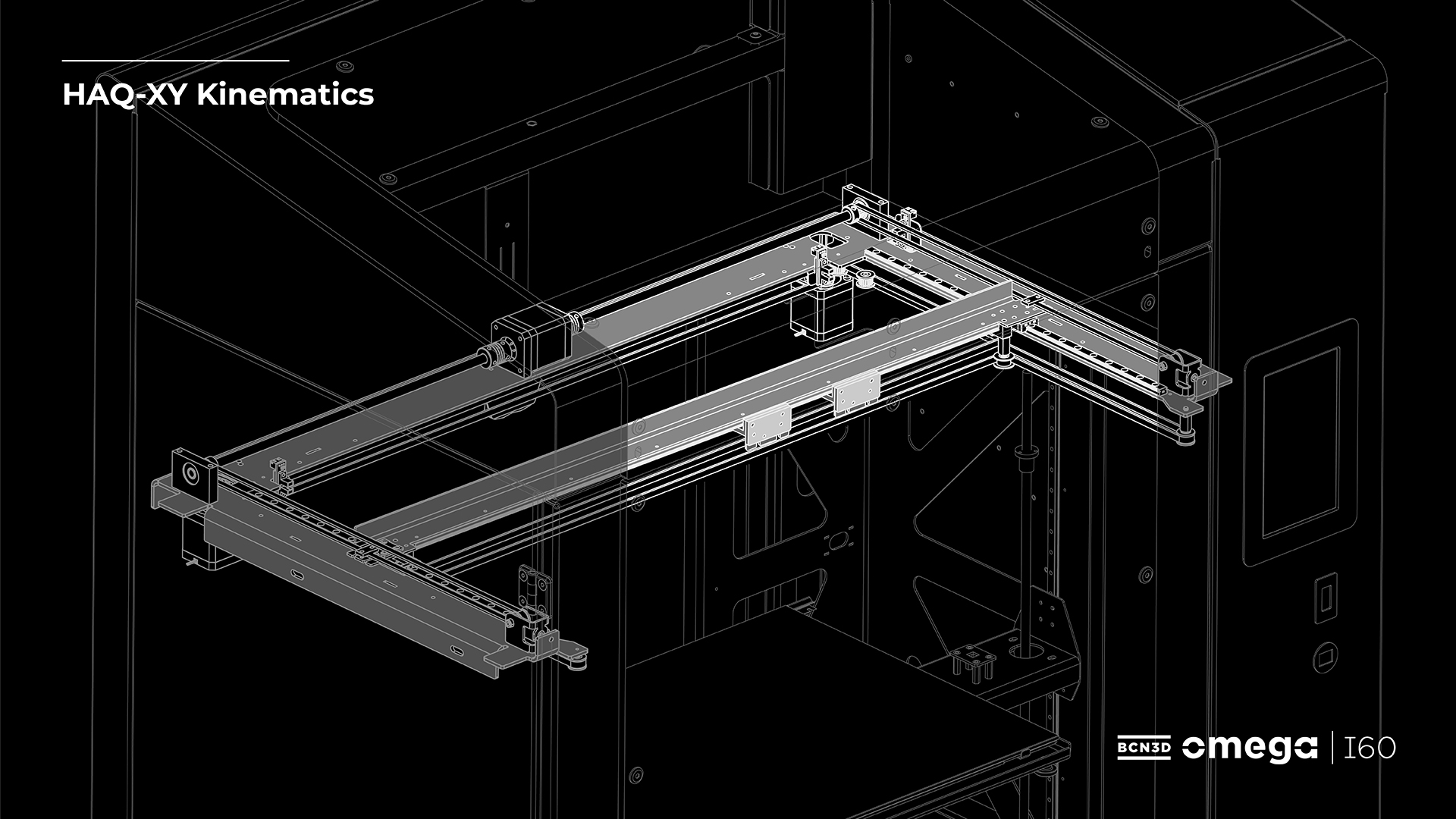

This motion architecture is considered one of the best systems for dual 3D printers and CNC machines, as it provides a lightweight, robust and precise approach. BCN3D Omega I60 utilizes an improved version of this kinematic system by placing the pulleys in a more optimal position. As a result, the system experiences a significant reduction in torsional moments along the X axis during the printing process.

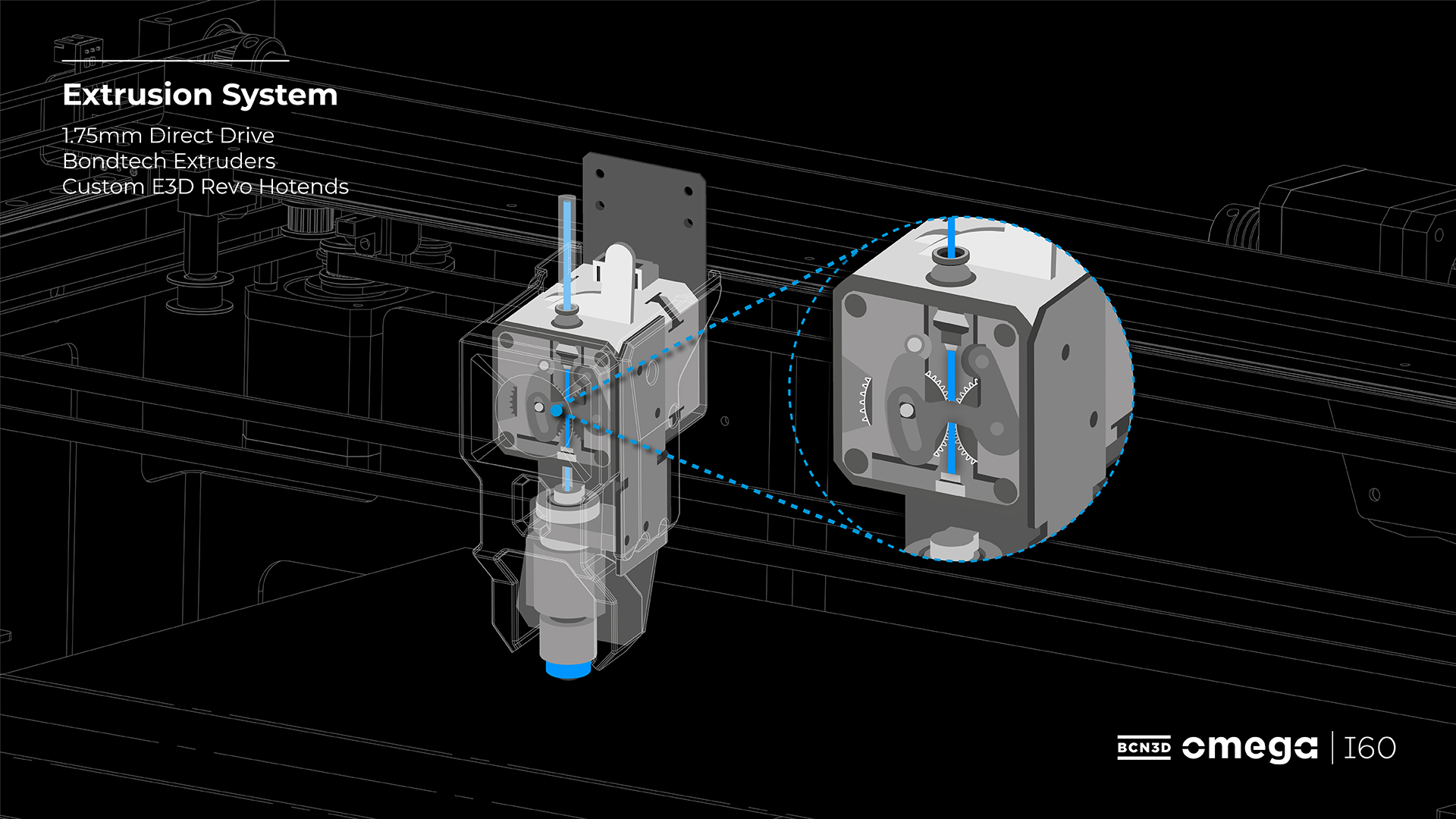

BCN3D Omega I60 equips a powerful extrusion system with industry-leading components, including 1.75 mm direct drive Bondtech LGX Pro extruders. This system provides more control and precision. It also includes custom E3D Revo hotends, which offer best-in-class extrusion reliability, as well as an easy-swap nozzle change.

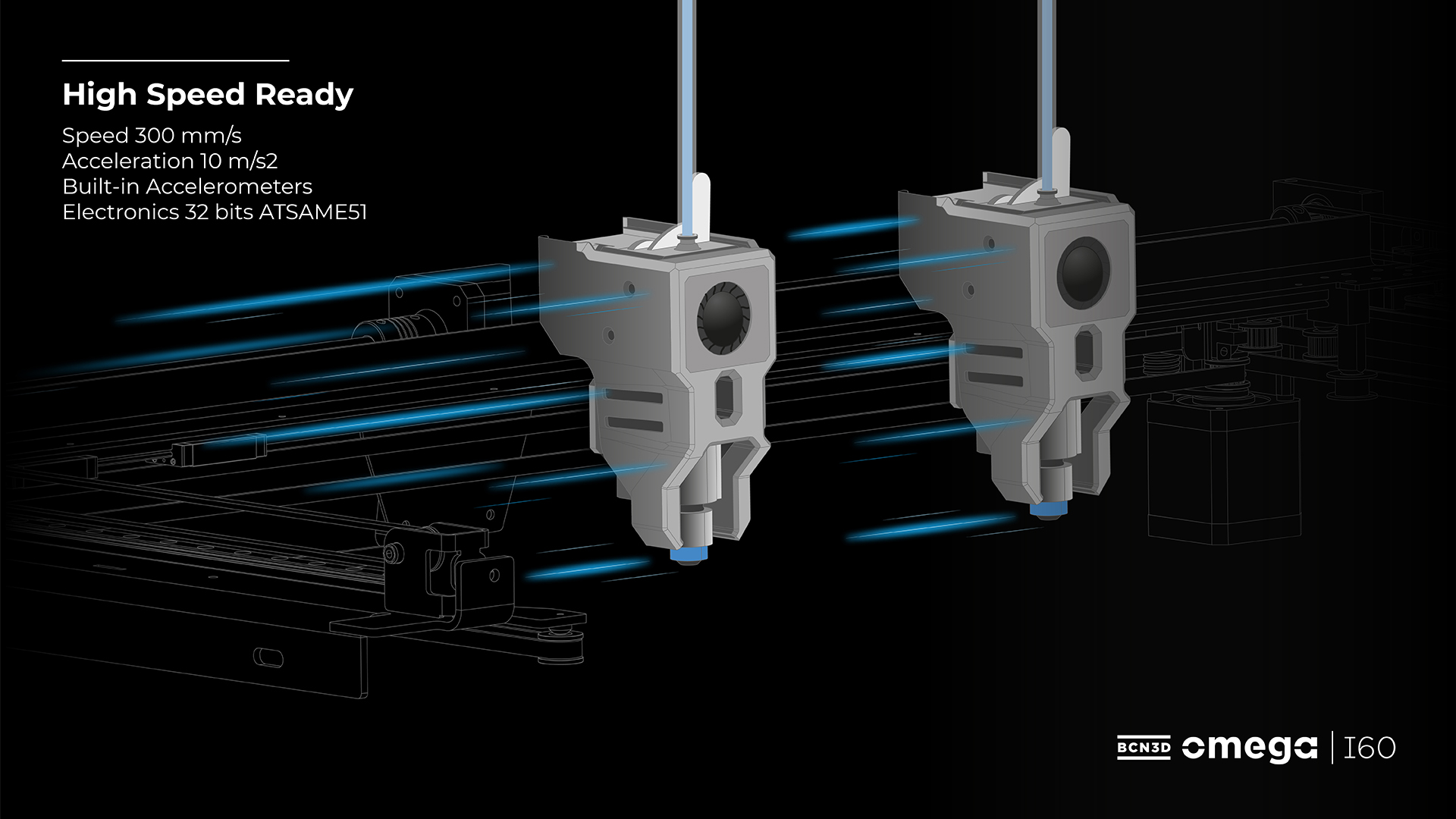

BCN3D Omega I60 is equipped with built-in accelerometers and 32-bit electronics, together with a custom version of Marlin 2.1. This combination enhances the capabilities of the BCN3D Omega I60, enabling it to efficiently manufacture parts at an impressive speed of 300 mm/s and achieve accelerations of 10 m/s².

A heated chamber facilitates the manufacturing of engineering polymers by maintaining an ideal temperature for the printable part throughout the printing process. The BCN3D Omega I60 heated chamber can reach temperatures of up to 70ºC, making it ideal for printing materials such as ASA, PA, ABS and reinforced PA, among others.

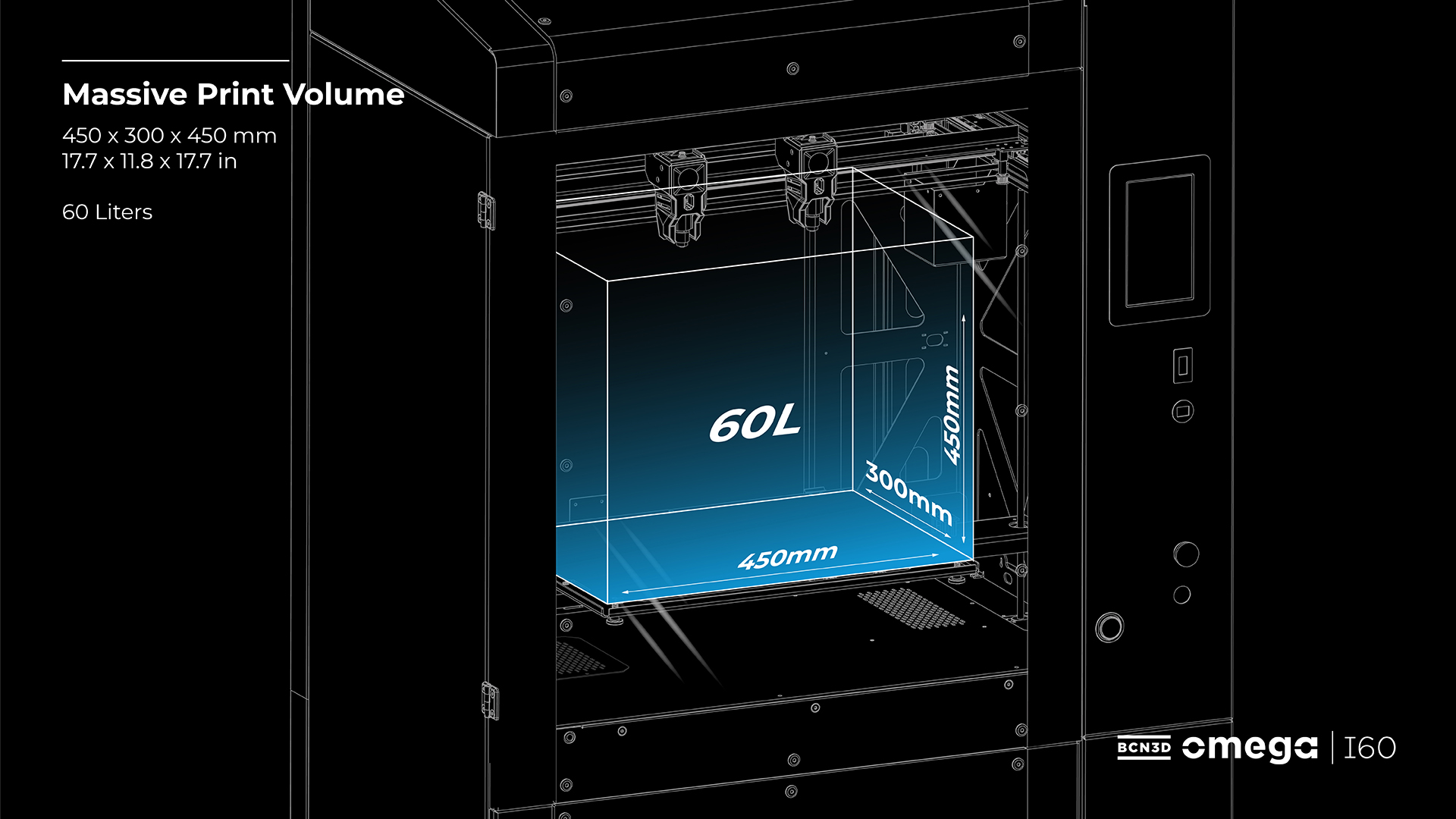

The printing volume available in the BCN3DOmega I60 is 450 x 300 x 450 mm (17.7 x 11.8 x 17.7 in), offering up to 60 liters. This, combined with the heated chamber, gives BCN3D Omega I60 the ability to produce large technical parts.

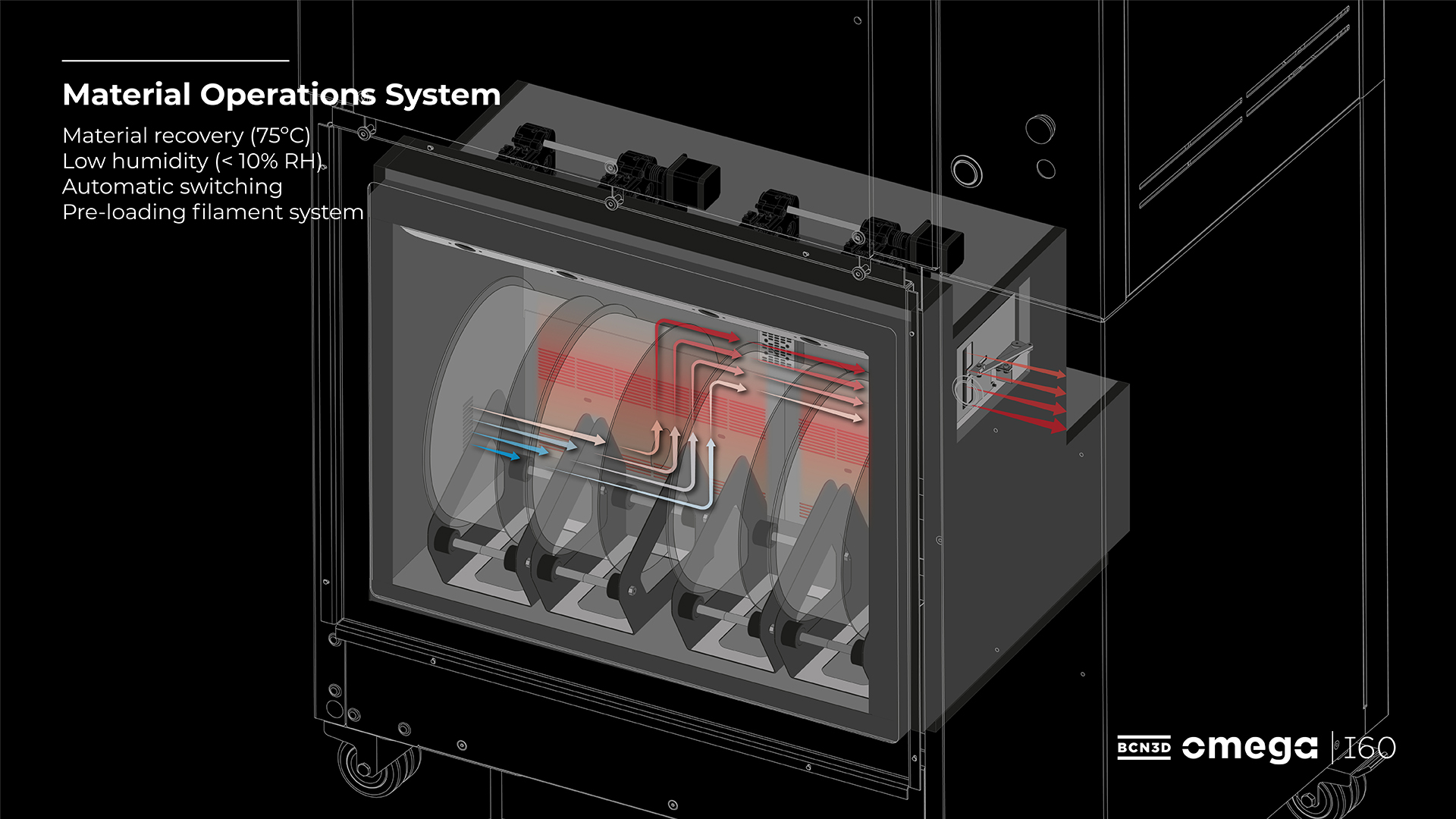

This integrated material module offers a complete all-in-one experience. The MOS allows you to control not only the humidity, but also the temperature. Furthermore, the material operating system enables automatic filament loading and unloading. BCN3D’s Omega I60 MOS can reach up to 75ºC and provides an RH below 10%.

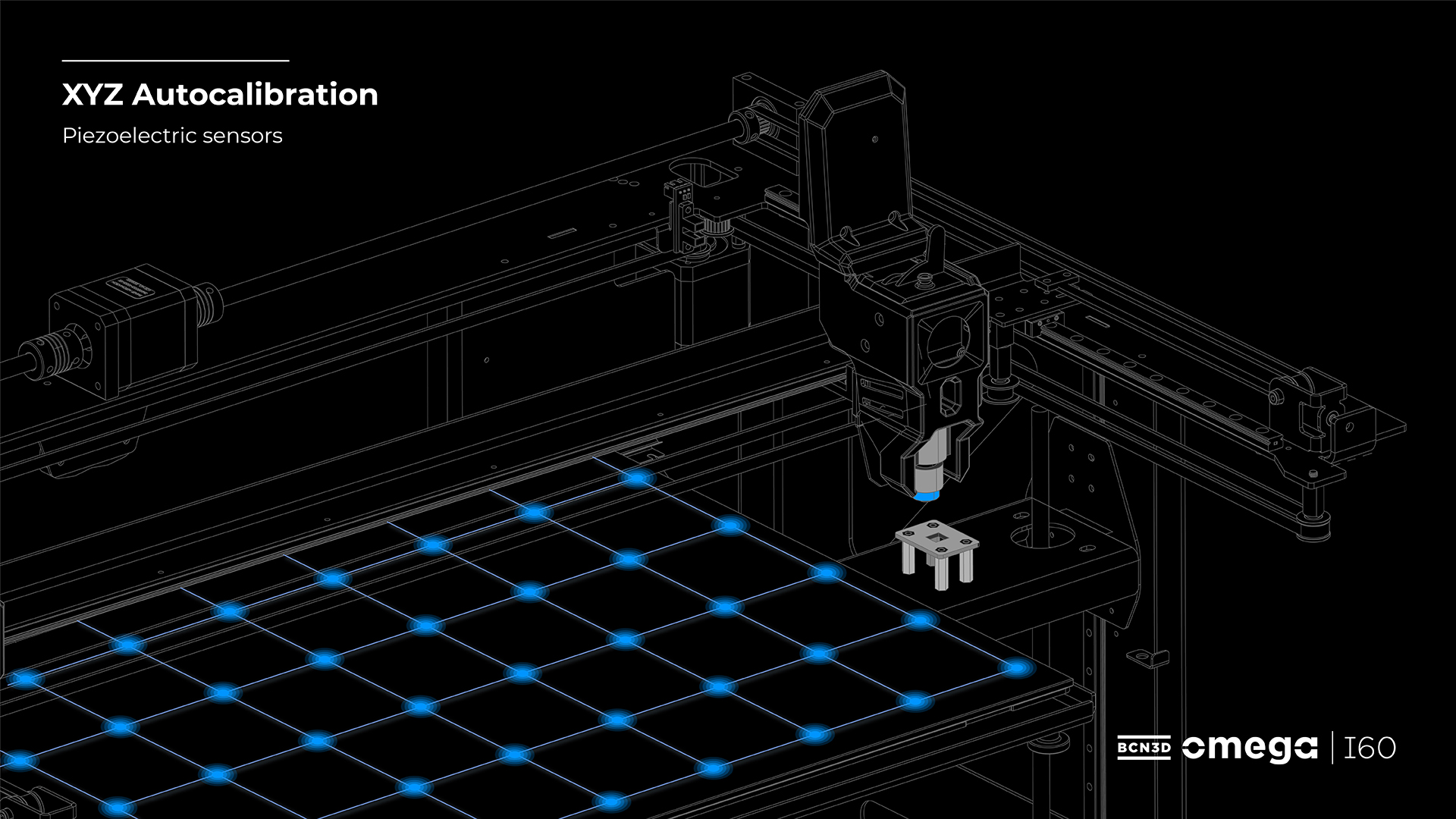

This technology, that uses piezoelectric sensors, eliminates human dependence and guarantees correct first layer adhesion. It calibrates by measuring multiple points to adjust printing surface height (Z) and (XY) offset between nozzles.

No customer reviews for the moment.