KIMYA - Embedding Additive into Manufacturing

A solution for manufacturers who wish to integrate additive manufacturing into their production processes for finished parts, tooling or quick prototyping. Kimya supports you in your R&D projects about materials for additive manufacturing.

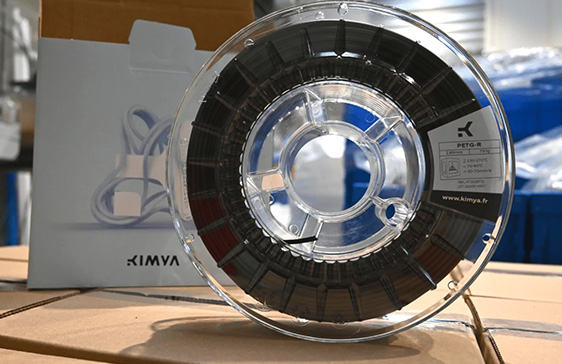

Ultra-resistant and high-performance 3D materials

Thanks to our expertise in the field of additive manufacturing, we have developed a vast range of 3D filaments enabling you to design all your projects in an instant. Every filament has been subjected to rigorous formulation, analysis and characterization conducted by the experts of the Kimya Lab. All the filaments have been tested and verified via a battery of printing simulations for different applications. A number of our materials have been designed and certified to provide resistance against high temperatures and solvents. Others can be used in food contact situations or in outdoor conditions.

Filaments ready to use

All our 3D filaments are accompanied by a detailed data sheet to help you make the right choices for your project and your specific printing and utilization constraints. We develop precise printing profiles to guarantee you the best possible result when developing your 3D parts in-house. However, our teams are also at your service to provide you with any advice you might need and to guide you towards the filament spools best suited to your application. Take advantage of their experience and recognized know-how in hi-tech additive manufacturing to achieve your best projects!

The "remake" line

3D printing is sustainable

- Less raw material needed – print with minimal waste

- Make parts locally

- More efficient design

- Print on demand – reduce inventory

- Repairability & spareparts

- Smaller, quieter factories

Post-industrial 3D filaments

- New life to industrial scrap

- Source known and controllable

- No variance in plastic composition

- Clean of debris, less contamination

- Technical properties close to standard filaments